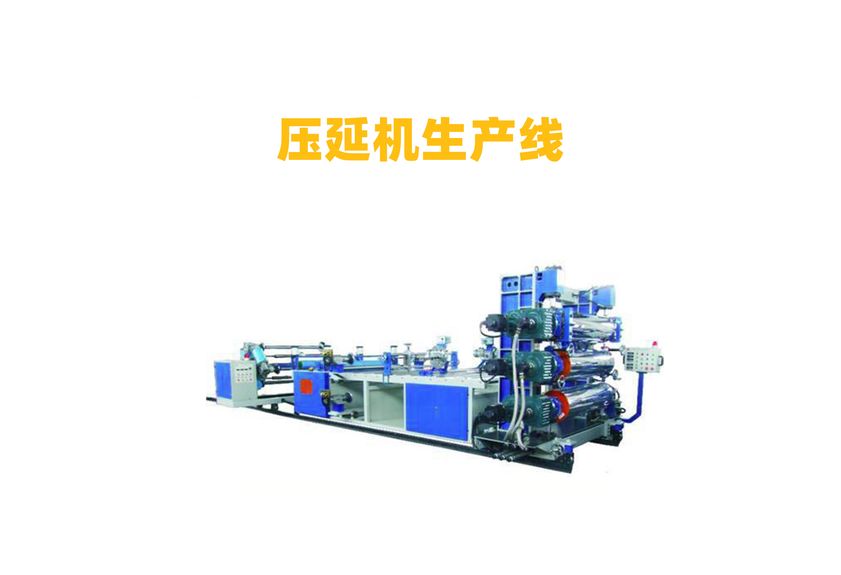

PTFE定向压延机:现代工业中的精密制造工具

The PTFE (Polytetrafluoroethylene) directed drawing machine is a highly sophisticated piece of equipment that has revolutionized the precision manufacturing industry. This machine plays a crucial role in the production of high-quality PTFE products, such as hoses, filters, and seals, which are widely used in various industries for their exceptional properties like low friction, high thermal resistance, and chemical resistance.

One of the key features of the PTFE directed drawing machine is its ability to precisely control the orientation of the PTFE fibers during the drawing process. This is achieved through the use of advanced computer-aided design software that allows operators to create intricate patterns and designs on the fabrication surface. The machine then uses a combination of mechanical and electrical systems to apply pressure and tension to the fabric, resulting in a uniform and consistent product with minimal defects.

Another advantage of the PTFE directed drawing machine is its ability to produce high-volume, low-cost products. By using automated processes and robotic arms, the machine can work at a much faster rate than traditional manual methods, reducing labor costs and increasing efficiency. Additionally, the machine's precision control ensures that each product meets stringent quality standards, making it an ideal choice for businesses looking to improve their competitiveness in the market.

In conclusion, the PTFE directed drawing machine is a game-changer in the precision manufacturing industry. Its ability to produce high-quality PTFE products with minimal defects and increased efficiency makes it an essential tool for any manufacturer looking to stay ahead in today's competitive market. As technology continues to advance, we can expect even more innovative solutions from this versatile machine, further enhancing our ability to manufacture high-value products with precision and ease.