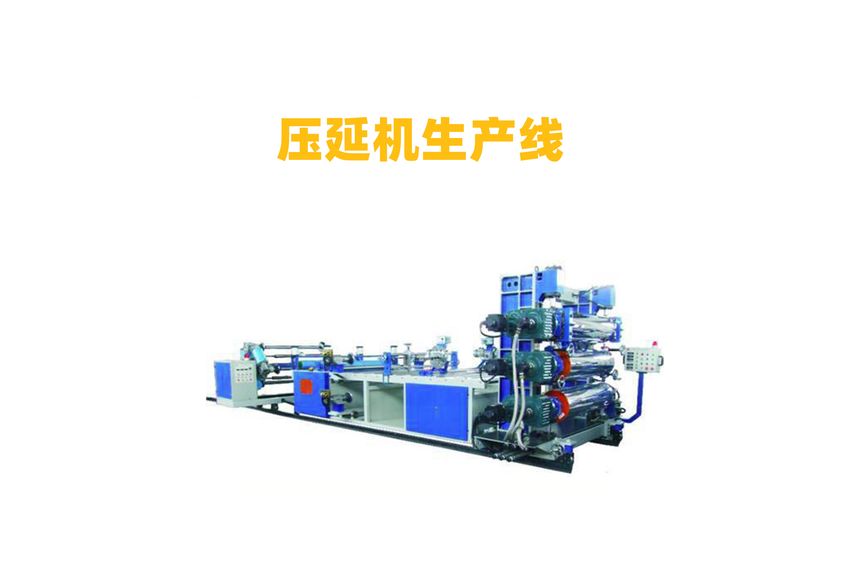

PTFE定向压延机:现代制造技术的关键

The PTFE (Polytetrafluoroethylene) Directional Rolling Machine is a revolutionary tool in the field of polymer processing. This machine plays a crucial role in the production of high-quality polytetrafluoroethylene (PTFE) products, which are widely used in various industries due to their exceptional properties such as non-stickiness, chemical resistance, and excellent thermal stability.

The PTFE Directional Rolling Machine utilizes advanced technology to achieve precise control over the orientation of the PTFE fibers during the rolling process. This technique allows for the creation of highly uniform and consistent PTFE sheets with minimal defects, ensuring superior performance in applications where smoothness and consistency are essential.

One of the key benefits of using the PTFE Directional Rolling Machine is its ability to produce PTFE sheets with a wide range of thicknesses and widths. This flexibility enables manufacturers to tailor their products to specific requirements, making it easier to meet the needs of different customers.

In addition to its technical advantages, the PTFE Directional Rolling Machine also offers significant cost savings compared to traditional methods of producing PTFE sheets. The machine's automated nature reduces labor costs, while its precision control ensures that materials are used efficiently, minimizing waste.

Overall, the PTFE Directional Rolling Machine represents a significant advancement in the field of polymer processing, offering manufacturers innovative solutions for producing high-quality PTFE products at competitive prices. As demand for these materials continues to grow, the importance of this technology cannot be understated, and its continued development will undoubtedly continue to shape the future of polymer manufacturing.