The Role of Radio Frequency Circuit Board Pressing Machine in the Production Line

The production line for radio frequency circuit boards is a crucial part of the electronics manufacturing process. It involves several steps, including material preparation, cutting and drilling, soldering, and final inspection. In this article, we will focus on the role of the radio frequency circuit board pressing machine in the production line.

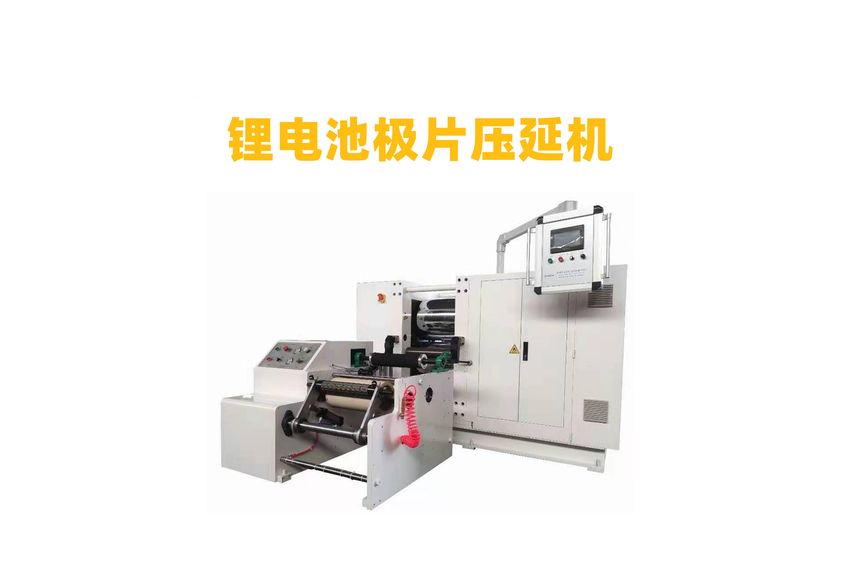

The pressing machine is an essential tool in the production line for radio frequency circuit boards. It is responsible for applying pressure to the circuit board during the soldering process. This pressure helps to ensure that the solder joints are properly formed and secure, preventing them from cracking or breaking during use.

The pressing machine consists of a motor-driven hydraulic cylinder that applies pressure to the circuit board. The hydraulic fluid inside the cylinder is pressurized by a pump, which is connected to a control system that regulates the pressure applied to the circuit board. The control system can be manually operated or automated, depending on the specific requirements of the production line.

The pressing machine is designed to handle different types of circuit boards, including those with different shapes and sizes. It has a variety of attachments that allow it to work with different tools, such as wire bonders, reflow ovens, and test equipment. This flexibility makes it possible to produce a wide range of radio frequency circuit boards quickly and efficiently.

In addition to its mechanical components, the pressing machine also includes software that controls the entire process. This software allows operators to monitor the progress of the production line and make adjustments as needed. It also provides data on the quality of the solder joints formed by the machine, allowing manufacturers to improve their products over time.

Overall, the role of the radio frequency circuit board pressing machine in the production line is critical to the success of the electronics industry. By ensuring that solder joints are properly formed and secured, the machine helps to prevent defects in the finished product and improves overall efficiency.