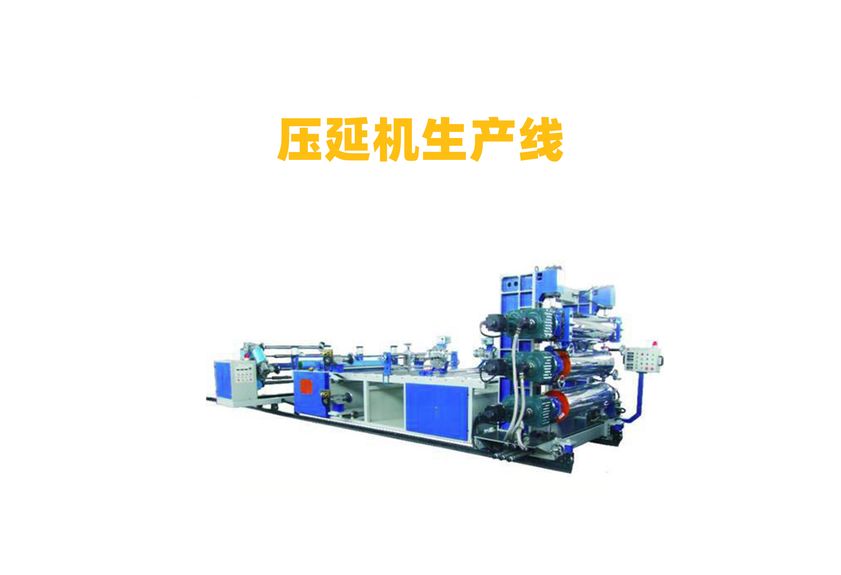

The Four-Roll Rolling Press: A Detailed Guide to Its Function, Applications, and Maintenance

The four-roll rolling press is a versatile tool used in the manufacturing industry for shaping metal sheets into various products. This machine is designed to produce sheet metal with consistent thickness and uniformity, which is essential for applications such as automotive bodies, aircraft parts, and electronic components. In this article, we will explore the functions of a four-roll rolling press, its applications, and some tips for maintaining it effectively.

Functions of a Four-Roll Rolling Press:

1. Shaping Metal Sheets: The four-roll rolling press is capable of shaping metal sheets into various shapes, including flat sheets, profiles, and profiles with rounded corners. This process involves feeding the sheet material through the rolls, which are arranged in a specific pattern to create the desired shape.

2. Thickness Control: The four-roll rolling press can be configured to control the thickness of the formed product. This feature is particularly useful in industries where precision in dimensions is crucial, such as automotive and aerospace.

3. Material Preparation: Before shaping, the four-roll rolling press can be used to prepare the sheet material by removing any burrs or impurities that may affect the final product quality.

4. Continuous Production: The four-roll rolling press can operate continuously, allowing for high production rates and efficiency in large-scale manufacturing operations.

Applications of a Four-Roll Rolling Press:

1. Automotive Industry: The four-roll rolling press is widely used in the automotive industry for producing body panels, door frames, and other structural components. It enables manufacturers to produce parts with precise dimensions and uniform thickness, which are critical for safety and durability.

2. Aerospace Industry: In the aerospace industry, the four-roll rolling press is used to produce complex shapes such as wings, fuselages, and engines. These components require high precision and consistency in thickness, making the four-roll rolling press an essential tool for aerospace manufacturers.

3. Electronics Industry: The four-roll rolling press is also used in the electronics industry for producing circuit boards, connectors, and other electrical components. The ability to control the thickness and uniformity of these products is crucial for ensuring reliable performance and longevity.

4. Other Manufacturing Industries: The four-roll rolling press is also utilized in other manufacturing industries such as steel, machinery, and plastics. Its ability to produce consistent products with precise dimensions makes it a valuable tool for these industries as well.

Tips for Maintaining a Four-Roll Rolling Press:

1. Regular Maintenance: Regular maintenance is essential for ensuring the longevity of a four-roll rolling press. This includes cleaning the machine's interior components, lubricating the rollers, and inspecting for any signs of wear or damage.

2. Proper Fuel and Lubricant Use: Ensure that the appropriate fuel and lubricant are used for the four-roll rolling press. Using the wrong type of fuel or lubricant can cause damage to the machine or reduce its efficiency.

3. Proper Loading and Unloading: When loading and unloading the four-roll rolling press, ensure that the material is properly loaded and unloaded to avoid damaging the machine or causing jams.

4. Regular Tuning: Regular tuning of the four-roll rolling press is necessary to maintain its optimal performance. This includes adjusting the tension on the rolls and checking for any adjustments that need to be made to ensure consistent results.

1. Four-Roll Rolling Press

2. Automotive Industry

3. Aerospace Industry

4. Electronics Industry

5. Maintenance Tips

The Four-Roll Rolling Press is a versatile tool used in the manufacturing industry for shaping metal sheets into various products. Its application ranges from automotive bodies to aircraft parts and electronic components, showcasing its importance in various industries. To maintain this powerful tool, regular maintenance is essential, including proper fuel and lubricant use, loading and unloading techniques, and regular tuning. By following these tips, you can ensure that your four-roll rolling press remains efficient and produces consistent results, ultimately benefiting your business.