The Role of Talc Powder Granulators in the Manufacturing Industry

The manufacturing industry is a complex and ever-evolving field, where innovation and efficiency are key factors in achieving success. One such area that has seen significant advancements in recent years is the production of granulated materials, particularly in the context of talc powder. Talc, a naturally occurring mineral with a wide range of applications in industries such as cosmetics, pharmaceuticals, and construction, requires precise control over its particle size distribution to ensure optimal performance. This is where talc powder granulators come into play, offering a reliable solution for producing high-quality granulated talc at scale.

At the heart of these granulators lies a process known as granulation, which involves the formation of small, uniform particles from larger raw materials. In the case of talc, this process is crucial for ensuring that the final product meets the desired specifications. Talc powder granulators use a variety of techniques to achieve this, including spray drying, fluidized bed granulation, and extrusion granulation. Each method has its own advantages and limitations, but they all share a common goal: to produce talc particles that are both efficient and cost-effective.

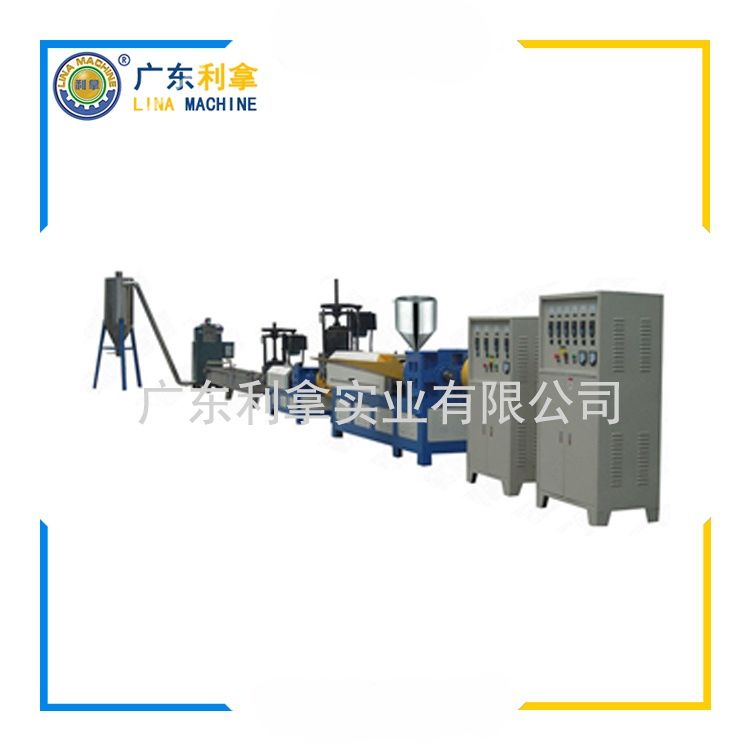

One of the key features of talc powder granulators is their ability to handle large volumes of material efficiently. This is achieved through advanced technology and design, allowing granulators to operate at high speeds and pressures without sacrificing quality or safety. Additionally, many granulators are equipped with automation systems that allow for precise control over the granulation process, making it possible to produce consistent results time after time.

Another important aspect of talc powder granulators is their ability to adapt to changing market demands. As the global cosmetics industry continues to evolve, so too does the need for talc products that meet specific standards and regulations. Talc powder granulators are designed to be flexible enough to accommodate these changes, allowing manufacturers to quickly adjust their processes and products to meet new requirements.

In conclusion, talc powder granulators are an essential part of the manufacturing industry, providing a reliable solution for producing high-quality granulated talc at scale. With their advanced technology and design, these granulators are capable of handling large volumes of material efficiently and adapting to changing market demands. As the industry continues to evolve, it is likely that we will see even more innovative solutions like these emerge, further enhancing our ability to produce high-quality materials at scale.