The Role of Thin Film Rolling Machines in Manufacturing

The thin film rolling machine is a crucial tool in the manufacturing industry, particularly in the production of thin films and coatings. These machines are designed to apply pressure and heat to thin materials, resulting in a uniform and consistent layer of material. In this article, we will explore the different types of thin film rolling machines available, their applications, and some tips for operating them effectively.

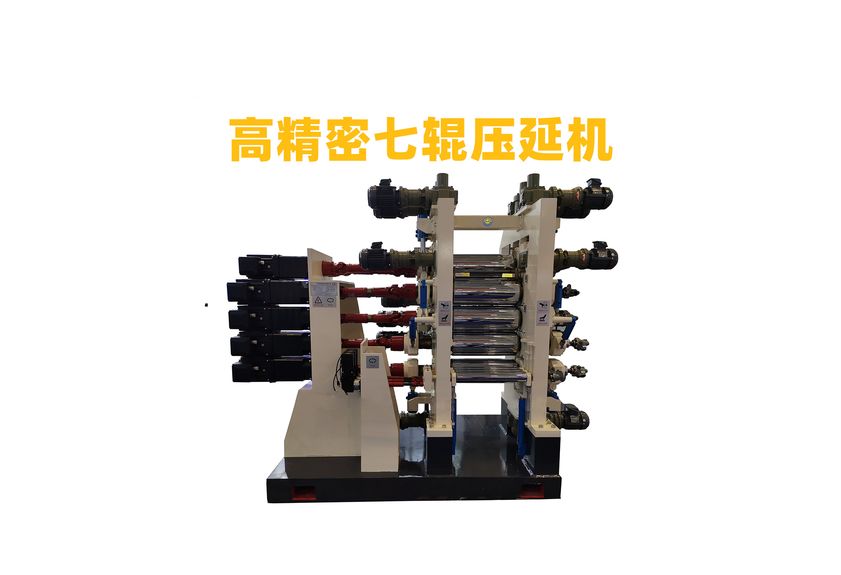

There are several types of thin film rolling machines, each with its own unique features and capabilities. Some of the most common types include:

1. Flat Roller Mills: These machines use rollers to roll and compress the material, resulting in a smooth and even surface. They are commonly used for producing films such as plastic, metal, and ceramics.

2. Cylinder Rollers: These machines use cylinder-shaped rollers to apply pressure and heat to the material. They are ideal for producing films made from polymers and other materials that have a high melting point.

3. Roller Mills: These machines combine the features of flat roller mills and cylinder rollers, allowing for more precise control over the thickness and quality of the film being produced.

Applications of thin film rolling machines are vast, ranging from consumer electronics to medical devices. For example, they are used to produce transparent conductive films for solar panels, anti-reflective coatings for lenses, and biocompatible coatings for implantable devices.

To operate a thin film rolling machine effectively, it is important to follow some basic guidelines. First, ensure that the machine is properly set up and calibrated before starting the process. This includes checking the rollers, temperature control, and pressure settings. Second, pay close attention to the material being processed, as variations in thickness or quality can affect the final product. Finally, regularly clean and maintain the machine to prevent wear and tear, which can lead to decreased efficiency and increased costs.

In conclusion, thin film rolling machines play a vital role in the manufacturing industry, enabling us to produce a wide range of materials with high quality and consistency. By understanding the different types of machines available and following proper operating procedures, manufacturers can achieve optimal results and meet the demands of their customers.