"The Role of Fluorocarbon Rubber Rolling Press in the Manufacturing Industry

Fluorocarbon rubber, also known as fluorocarbon or FKM, is a high-performance synthetic rubber that has found extensive applications in various industries due to its exceptional properties such as high strength, excellent resistance to chemicals, and superior thermal stability. One of the key equipment used in the production of fluorocarbon rubber is the rolling press, which is specifically designed for processing this material. This article will discuss the role of the fluorocarbon rubber rolling press in the manufacturing industry and its impact on the overall process.

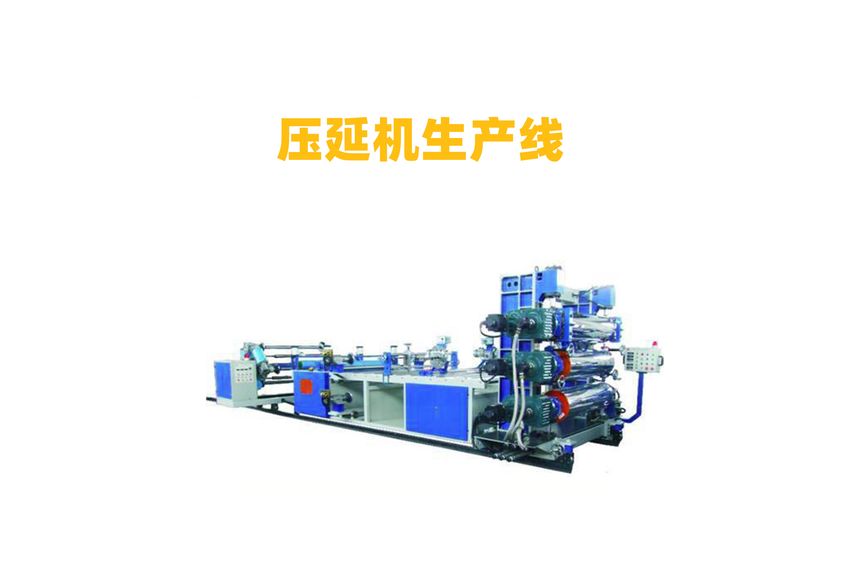

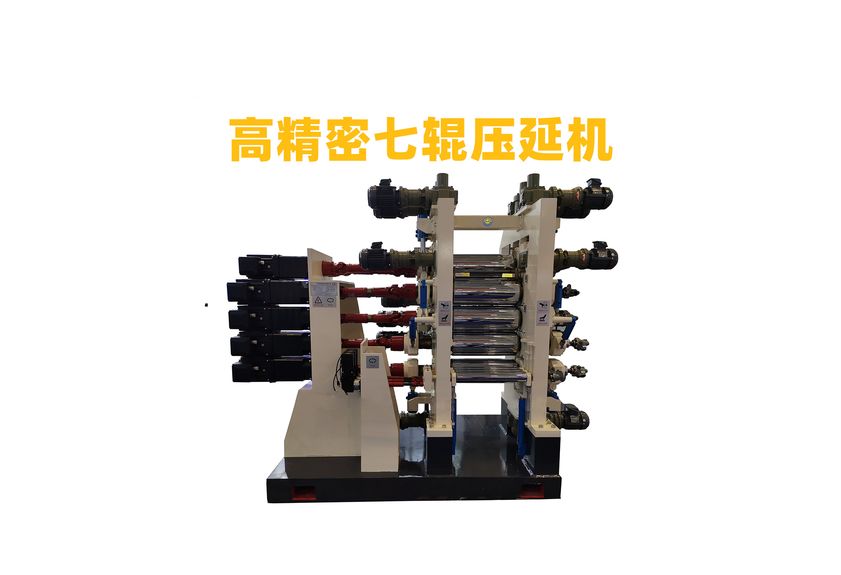

The fluorocarbon rubber rolling press is an essential piece of machinery used in the production of fluorocarbon rubber. It is a large-scale machine that uses rollers to extrude and process the raw materials into a uniform sheet of fluorocarbon rubber. The rolling press consists of several components, including the main frame, rollers, drive mechanism, and control system. The main frame supports the entire machine and provides a stable platform for the rollers to rotate. The rollers are made of high-strength materials and are arranged in a specific pattern to ensure even extrusion of the raw materials. The drive mechanism drives the rollers to rotate and maintain a consistent speed during the processing process. The control system monitors the operation of the rolling press and adjusts the parameters accordingly to achieve optimal results.

The fluorocarbon rubber rolling press plays a crucial role in the manufacturing process of fluorocarbon rubber. It is responsible for extruding and processing the raw materials into a uniform sheet of fluorocarbon rubber. The rollers used in the rolling press have a significant impact on the quality of the final product. The rollers need to be made of high-strength materials with good wear resistance and heat resistance to ensure that they can withstand the high temperatures and pressures generated during the processing process. Additionally, the rollers need to be precisely aligned to ensure that the raw materials are evenly extruded and processed.

The fluorocarbon rubber rolling press is not only used in the manufacturing of fluorocarbon rubber but also has other applications in various industries. For example, it can be used in the production of automotive parts, electronic devices, and other high-performance materials. The advantages of using the fluorocarbon rubber rolling press include increased efficiency, reduced labor costs, and improved product quality. By using this equipment, manufacturers can produce high-quality fluorocarbon rubber products quickly and efficiently, which is beneficial for their competitiveness in the market.

In conclusion, the fluorocarbon rubber rolling press is an essential piece of machinery used in the manufacturing industry for the production of fluorocarbon rubber. Its precise alignment, high-strength rollers, and efficient operation contribute to the production of high-quality fluorocarbon rubber products. As the demand for fluorocarbon rubber continues to increase, the use of this equipment will become increasingly important for manufacturers looking to meet the demands of the market.