The Art of Wood Moulding Machinery

In the realm of industrial woodworking, the art of molding has been a staple for centuries. At its core lies the humble but powerful machine - the wood moulding machine. This versatile tool is not just a mere mechanical device; it's a testament to human ingenuity and craftsmanship.

The wood moulding machine is a marvel of modern technology that has revolutionized the way we shape and form wood into intricate shapes. It's an instrument that can take a piece of raw wood and transform it into something as beautiful as a sculpture or as functional as a furniture piece.

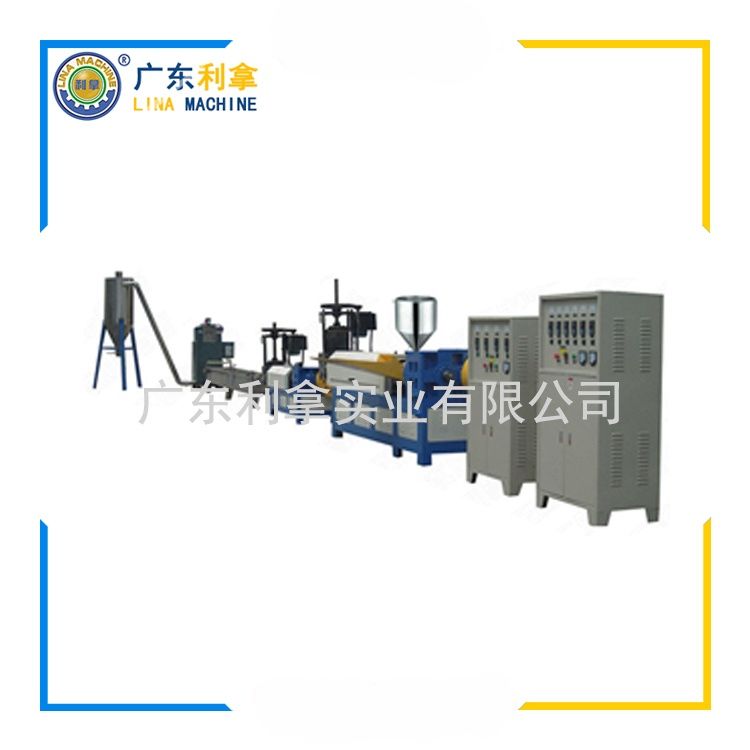

At its core, the wood moulding machine is a complex assembly of gears, motors, and other components that work together seamlessly to create the desired shape. The machine typically consists of a base plate, a headstock, and a tailstock. The base plate houses the power source, while the headstock holds the die or mold that will be used to shape the wood. The tailstock is responsible for holding the workpiece in place while the die is being applied.

The process begins with selecting the right type of wood for the project. Once the wood is cut to the desired size and shape, it's ready to be molded. The operator then positions the die on the headstock and applies pressure to the tailstock, causing the wood to conform to the shape of the die. The machine then locks down the die and starts the curing process, which usually involves heating the wood to a specific temperature to harden it.

Once the wood has cured, it's ready to be removed from the die. The operator carefully removes the die and inspects the finished product. If everything looks good, the machine can be reused for another project. However, if there are any flaws or imperfections, the operator may need to adjust the die or use a different technique to achieve the desired result.

The wood moulding machine is a versatile tool that can be used for a wide range of projects. From small-scale woodworking projects to large-scale furniture production, this machine has become an essential part of many woodworkers' toolkits. Its ability to produce high-quality products at a fast pace has made it a popular choice among hobbyists and professionals alike.

1. Wood Moulding Machine

2. Industrial Woodworking

3. Technological Innovation

4. Craftsmanship

5. Functional Pieces

This article delves into the fascinating world of wood moulding machines, highlighting their importance in industrial woodworking. By exploring the intricate workings of these machines and their applications in various industries, we provide readers with an insight into the cutting-edge technology behind the creation of high-quality wood products. Whether you're a seasoned woodworker or simply interested in learning more about this fascinating craft, this article is sure to captivate your attention and inspire your creativity.