The Importance of Rubber Extrusion Filters in the Manufacturing Process

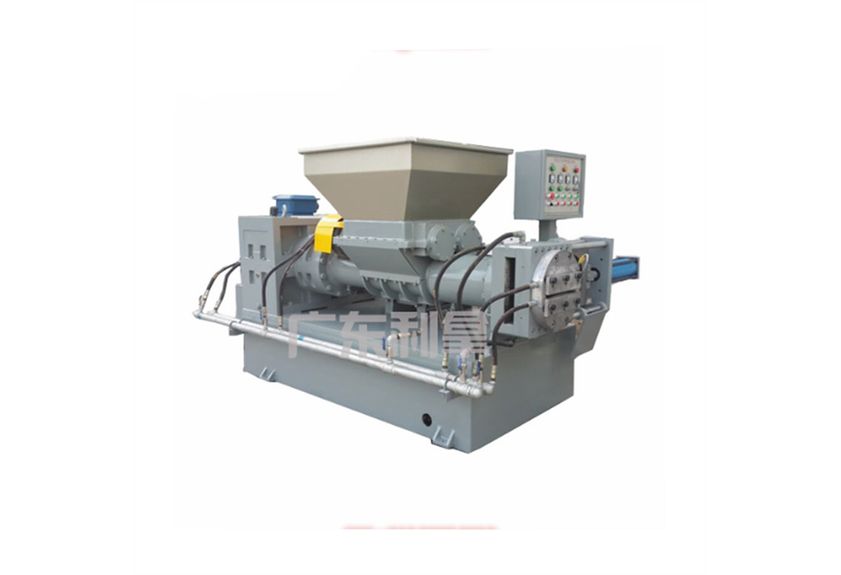

In the manufacturing industry, rubber products are essential components that play a crucial role in various applications. One of the critical steps in the production process is the use of rubber extruders, which involve the process of mixing and shaping raw materials into finished products. However, during this process, there are certain impurities that need to be removed to ensure the quality and consistency of the final product. This is where rubber filters come into play.

Rubber filters are designed to remove impurities from the rubber mixture before it is extruded. They work by trapping particles and other unwanted materials in their filtering chambers, which are then discharged through a separate outlet. This process helps to maintain the quality of the final product and ensures that it meets the required standards for use.

The importance of rubber filters cannot be overstated, as they play a vital role in the overall quality control of the rubber manufacturing process. By removing impurities, they help to improve the performance and durability of the final product, making it more reliable and efficient. Additionally, they contribute to reducing waste and minimizing environmental impact by ensuring that only high-quality materials are used in the production process.

In conclusion, rubber filters are essential tools in the manufacturing process of rubber products. They help to remove impurities and ensure the quality of the final product, contributing to the overall success of the manufacturing process. As such, it is important for manufacturers to invest in proper rubber filters to meet the requirements of their customers and maintain their reputation in the industry.