The Role of the Slag Rolling Machine in the Manufacturing Industry

The slab rolling machine, also known as a slag rolling machine, is an essential piece of equipment used in the manufacturing industry. It is responsible for shaping and refining raw materials into finished products. In this article, we will explore the various functions of the slab rolling machine and its impact on the manufacturing process.

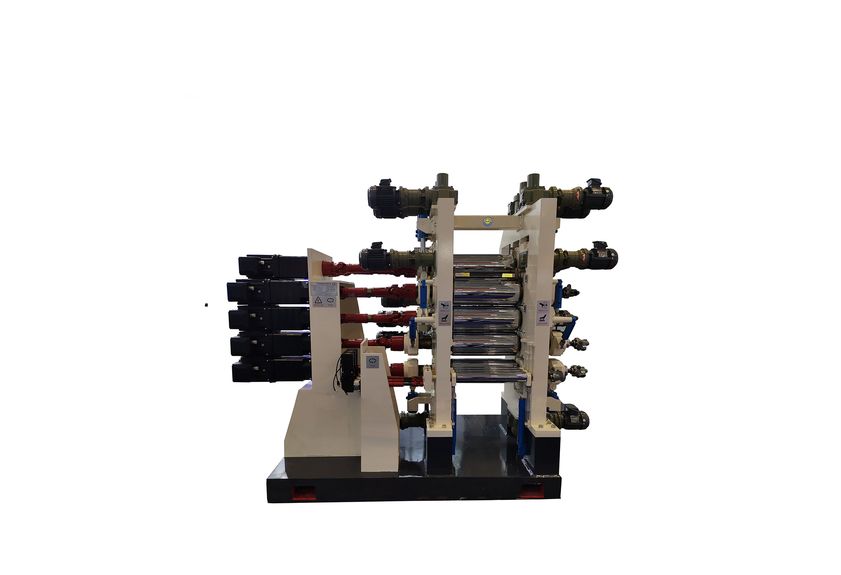

Firstly, the slab rolling machine is used to shape and refine metal sheets. This process involves rolling the metal sheets between two rollers, which are mounted on a frame. The rollers are made of high-quality steel and are designed to withstand high temperatures and pressure. The machine's precision rollers ensure that the metal sheets are evenly shaped and have consistent thickness.

Secondly, the slab rolling machine is used to remove defects from metal sheets. During the shaping process, some imperfections may occur, such as scratches or dents. These defects can affect the quality and appearance of the finished product. The slab rolling machine uses its advanced technology to detect and remove these defects before they become visible to the customer.

Thirdly, the slab rolling machine is used to produce thin sheets of metal. Thin sheets are often used in electronics, where they provide better conductivity and heat dissipation. The slab rolling machine can produce thin sheets up to several millimeters thick, which meets the needs of different industries.

Fourthly, the slab rolling machine is used to produce large sheets of metal. Large sheets are often used in construction, where they provide greater strength and durability. The slab rolling machine can produce large sheets up to several meters in length, which meets the needs of different industries.

Fifthly, the slab rolling machine is used to produce sheets with specific shapes and sizes. Different industries have different requirements for sheet shapes and sizes. The slab rolling machine can produce sheets with various shapes and sizes, which meets the needs of different industries.

Sixthly, the slab rolling machine is used to improve the efficiency of the manufacturing process. By using the slab rolling machine, manufacturers can reduce the time and labor required for sheet shaping and defect removal. This leads to increased production capacity and reduced costs.

Seventhly, the slab rolling machine is used to improve the quality of the finished product. By using the slab rolling machine, manufacturers can ensure that the metal sheets are evenly shaped, free from defects, and meet the specifications of different industries. This leads to higher customer satisfaction and better brand reputation.

Eighthly, the slab rolling machine is used to improve safety and environmental protection. The slab rolling machine uses advanced technology to detect and remove defects before they become visible to the customer. This reduces the risk of accidents caused by improperly shaped or defective sheets. Additionally, the slab rolling machine uses energy-efficient motors and controls to minimize waste and emissions during operation.

In conclusion, the slab rolling machine plays a crucial role in the manufacturing industry. Its ability to shape, refine, remove defects, produce thin sheets, large sheets, sheets with specific shapes and sizes, improve efficiency, quality, safety, and environmental protection makes it an essential tool for modern manufacturing. As technology continues to advance, the slab rolling machine will continue to evolve and improve, further enhancing the manufacturing process and driving innovation in the industry.