Understanding the Advantages of Silicone Rubber Filter Extrusion Machines

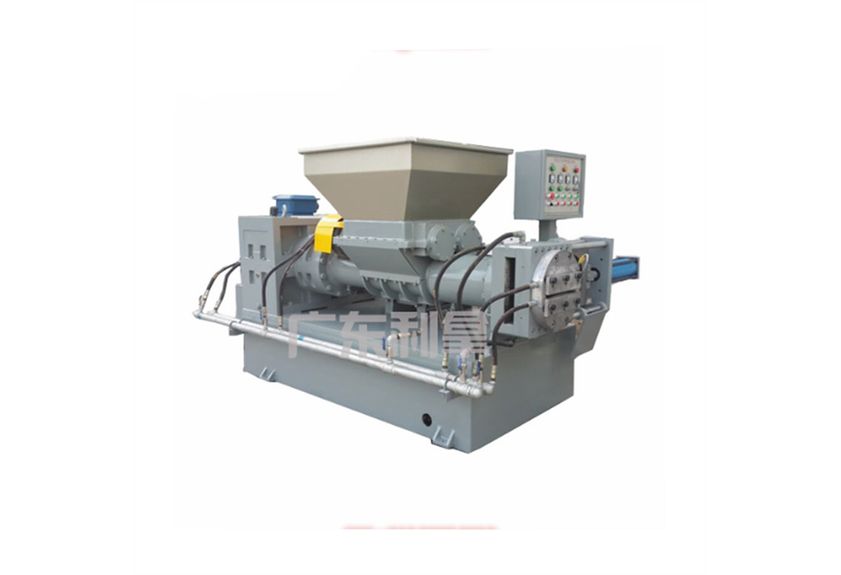

Silicone rubber filters are an essential part of many industries, including healthcare, food processing, and environmental protection. The silicone rubber filter extrusion machine is a crucial tool in the production process of these filters. In this article, we will explore the advantages of using silicone rubber filters and their associated silicone rubber filter extrusion machines.

Firstly, silicone rubber filters have excellent filtration performance. They can effectively trap particles and contaminants from the air or liquid, making them ideal for use in various applications. Additionally, silicone rubber filters are highly resistant to chemicals and solvents, ensuring that they remain effective even under harsh conditions.

Secondly, silicone rubber filter extrusion machines are highly efficient and cost-effective. These machines can produce high-quality silicone rubber filters at a lower cost than traditional methods. This makes them an attractive option for businesses looking to reduce their expenses while still maintaining high-quality products.

Thirdly, silicone rubber filter extrusion machines are easy to operate and maintain. They require minimal maintenance and can be easily cleaned and disassembled for servicing. This makes them ideal for small-scale operations or those with limited resources.

Fourthly, silicone rubber filter extrusion machines are eco-friendly. They produce no harmful emissions or pollutants during operation, making them a sustainable choice for businesses looking to minimize their environmental impact.

Finally, silicone rubber filter extrusion machines offer a wide range of customization options. Businesses can choose from different sizes, shapes, and materials to meet their specific needs and preferences.