The Role of Large-Scale Mixing Machines in the Manufacturing Industry

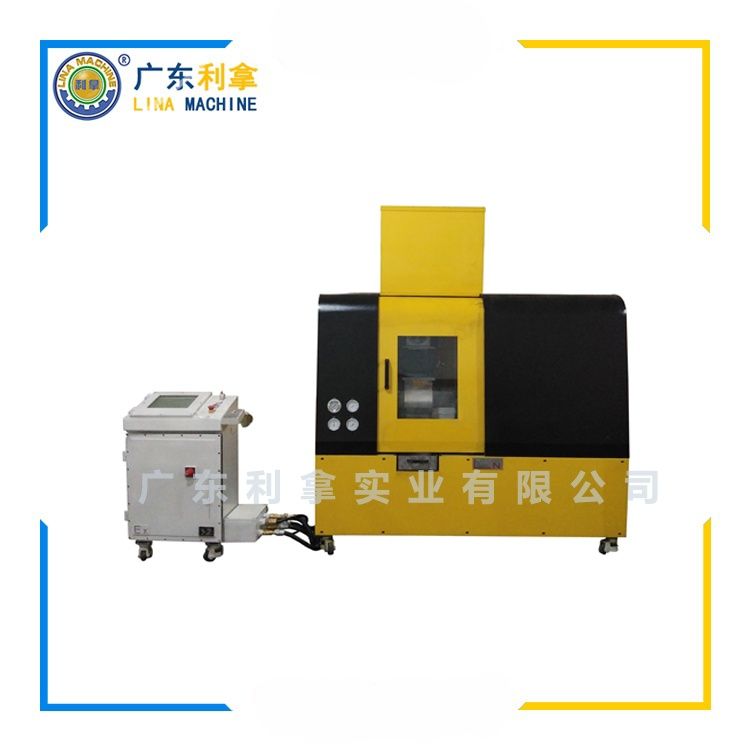

In the manufacturing industry, large-scale mixing machines play a crucial role in ensuring the quality and consistency of raw materials. These machines are designed to handle large batches of materials at high speeds, making them ideal for industries such as food processing, pharmaceuticals, and chemical manufacturing.

One of the main benefits of using large-scale mixing machines is their ability to process large quantities of material efficiently. This is particularly important in industries where time is of the essence, such as food production or pharmaceutical manufacturing. By reducing the time it takes to mix and blend materials, these machines can help companies save on labor costs and improve productivity.

Another advantage of large-scale mixing machines is their ability to produce consistent results. Unlike smaller machines that may produce inconsistent output due to manual adjustments, large-scale machines are designed to operate with precision and accuracy. This means that the final product will be consistent across different batches, which is essential for many industries.

In addition to their technical advantages, large-scale mixing machines also have a positive impact on the environment. By reducing the need for manual labor and minimizing waste, these machines can help reduce energy consumption and greenhouse gas emissions. This not only helps to conserve resources but also contributes to a more sustainable future.

When selecting a large-scale mixing machine, it is important to consider factors such as capacity, speed, and ease of maintenance. Companies should also evaluate their specific needs and budget to determine which machine is best suited for their operations.

1. large-scale mixing machines

2. manufacturing industry

3. efficiency

4. consistency

5. environmental impact

This article provides an in-depth analysis of the role of large-scale mixing machines in the manufacturing industry. We discuss the benefits of these machines, including their ability to process large quantities of material efficiently and produce consistent results. We also explore the environmental benefits of using these machines, highlighting their ability to reduce energy consumption and greenhouse gas emissions. Finally, we provide tips on selecting the right machine for your specific needs and budget.