The Art of Rubber Extrusion: Understanding the Rubber Extrusion Machine

The rubber extrusion machine is a crucial tool in the production process of various rubber products. It is a high-pressure, high-temperature equipment that uses heat and pressure to convert raw materials into finished products. In this article, we will explore the basic principles of rubber extrusion, its applications, and how to maintain and operate this valuable machinery.

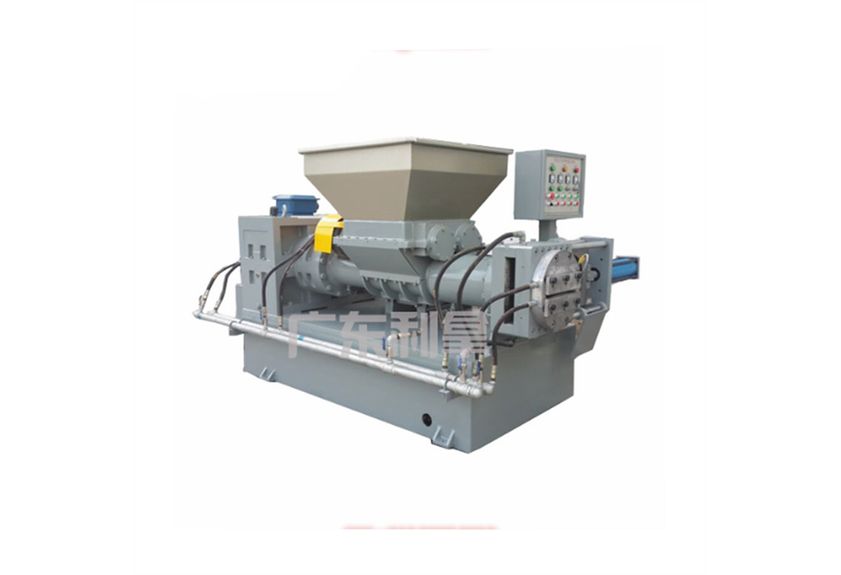

Firstly, let's understand what a rubber extruder is. A rubber extruder is a machine used for processing rubber materials, such as natural rubber, synthetic rubber, and elastomers. It consists of a barrel, screw, die, and other components that work together to convert raw materials into finished products. The barrel contains the rubber material, which is heated and mixed with other ingredients before being forced through the die by the screw. The die determines the shape and size of the final product, while the screw rotates continuously to ensure even mixing and distribution of the ingredients.

Now that we have a basic understanding of the rubber extruder, let's discuss its applications. Rubber extrusion machines are widely used in the automotive, aerospace, construction, and other industries. They can be used to produce tires, hoses, seals, and other rubber products. For example, tire manufacturers use rubber extruders to produce tires with different patterns and sizes. Similarly, aerospace companies use rubber extruders to produce parts like airbags and shock absorbers.

In addition to their practical applications, rubber extruders also play an important role in research and development. Many companies invest in research and development to develop new materials and processes that can improve the performance and durability of their products. This includes using advanced techniques such as injection molding, compression molding, and blow molding to create complex shapes and designs.

Now that we have discussed the basic principles and applications of rubber extrusion machines, let's talk about how to maintain and operate this valuable machinery. Firstly, it is essential to regularly clean the rubber extruder to remove any debris or impurities that may affect the quality of the final product. Secondly, proper maintenance of the machine is crucial to ensure its longevity and efficiency. This includes checking the screw and barrel for wear and tear, lubricating the moving parts, and inspecting the temperature and pressure settings. Finally, operators should follow safety guidelines when operating the rubber extruder, including wearing appropriate protective gear and following proper procedures for handling and disposing of hazardous materials.

In conclusion, the rubber extruder is a versatile and essential piece of equipment in the production process of various rubber products. By understanding its basic principles and applications, as well as maintaining and operating it properly, we can ensure that this valuable machinery continues to contribute to our industry's success.