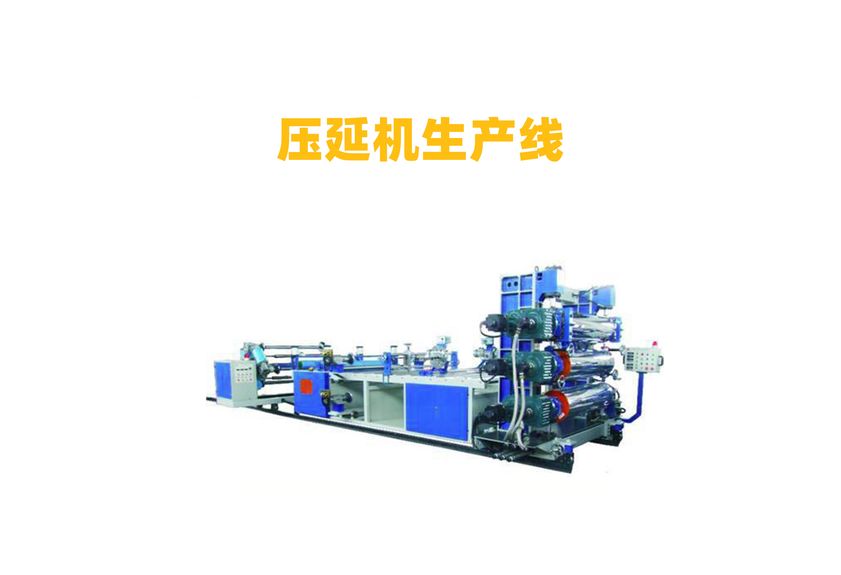

The Role of Silicone Rolling Press in Manufacturing

The silicone rolling press is a crucial tool in the manufacturing industry, particularly in the production of flexible and durable materials such as silicone rubber. This versatile machine is used to create sheets of silicone rubber that are then used in various applications, from automotive seals to medical implants.

The process begins with a mixture of silicone and other ingredients, which is then poured onto a rotating roller. As the roller moves, it applies pressure to the mixture, causing it to flow and form a continuous sheet. The roller then continues to move, creating a uniform and consistent layer of silicone rubber.

One of the key advantages of using a silicone rolling press is its ability to produce high-quality sheets of silicone rubber. The roller is designed to apply even pressure, ensuring that the silicone rubber forms a smooth and even surface. Additionally, the roller is made of high-quality materials, which helps to reduce wear and tear over time.

Another important aspect of the silicone rolling press is its ability to handle different types of silicone rubber. The machine can be customized to produce sheets of silicone rubber with different thicknesses and textures, depending on the application. This flexibility allows manufacturers to tailor their products to meet specific needs and requirements.

In conclusion, the silicone rolling press is an essential tool for the manufacturing industry. Its ability to produce high-quality silicone rubber sheets and its customizability make it a valuable asset for many industries. By utilizing this machine, manufacturers can create innovative and functional products that meet the demands of today's market.