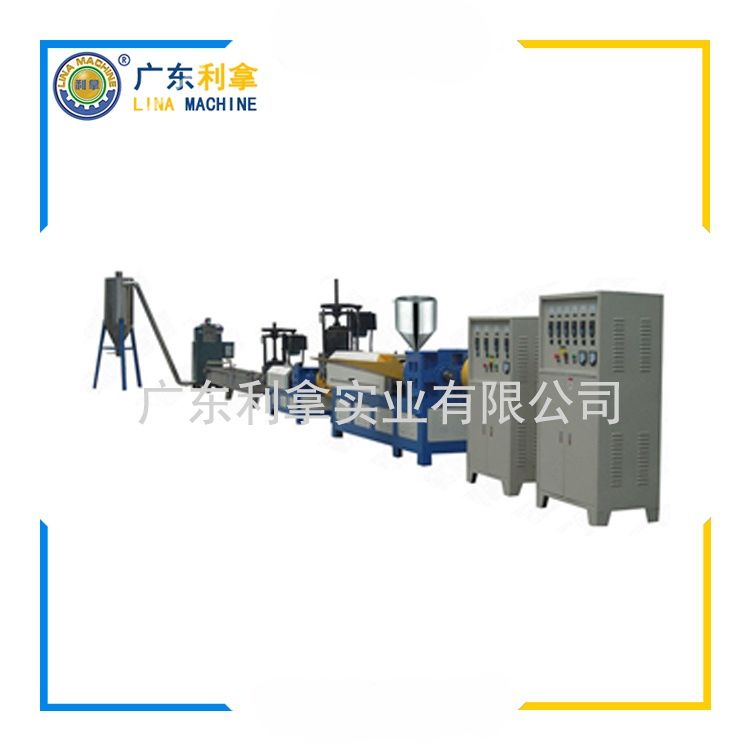

The Modified Melt Extrusion Cold Cutting Pellet Production Line

The production line for modifier melt extrusion cold cutting pellets is a crucial component in the pharmaceutical, food, and other industries. This article will provide an overview of this production line, including its design, components, and key processes.

The modifier melt extrusion cold cutting pellet production line is designed to produce high-quality pellets with consistent size and shape. It consists of several key components, including the melt extruder, cold cutter, pelletizer, and packaging equipment.

The melt extruder is responsible for converting the raw material into a uniform melt that can be extruded through the die. The melt temperature, pressure, and flow rate are all critical factors that affect the quality of the final product.

The cold cutter is used to remove excess material from the extruded pellets before they reach the packaging equipment. This process ensures that the pellets have a consistent size and shape throughout the production line.

The pelletizer is responsible for further shaping the pellets into the desired size and shape. This process may involve additional processing steps such as compression or granulation.

Finally, the packaging equipment is used to package the finished pellets for sale or storage. This equipment may include bags, boxes, or other containers depending on the specific application.

Key Processes:

1. Melt Extrusion: The raw material is melted and extruded through a die to form a continuous filament.

2. Cold Cutting: The filament is then cut into individual pellets using a cold cutter.

3. Pelletization: The pellets are further shaped and compacted to ensure consistency in size and shape.

4. Packaging: Finally, the finished pellets are packaged for sale or storage.

1. Modifier Melt Extrusion Cold Cutting Pellet Production Line

2. Pellet Production Line

3. Key Processes

4. Pharmaceutical Industry

5. Food Industry

6. Quality Control

7. Packaging Equipment

8. Continuous Filament

9. Cold Cutting

10. Pelletization

11. Consistency in Size and Shape

12. Pharmaceutical Applications

13. Food Applications

14. Quality Control Measures

15. Packaging Solutions

16. Continuous Filament Production

17. Cold Cutting Technology

18. Pelletization Techniques

19. Packaging Equipment Design

20. Quality Assurance Standards

This article provides an in-depth analysis of the modifier melt extrusion cold cutting pellet production line, highlighting its key components and processes. The production line is designed to produce high-quality pellets with consistent size and shape, which are essential for various applications such as pharmaceutical, food, and other industries. The article discusses the importance of quality control measures in ensuring consistent product quality throughout the production line. Additionally, it explores the latest technological advancements in cold cutting technology and pelletization techniques, which are critical for maintaining the consistency of the final product. Overall, this article aims to provide readers with a comprehensive understanding of the modifier melt extrusion cold cutting pellet production line and its impact on industry standards.