Innovative Advances in Liquid Thermal Conductive Silica Film Rolling Machinery

The field of electronics and aerospace technology has seen a significant surge in demand for high-performance thermal interface materials. One such material that has gained immense attention is the liquid thermal conductive silicone (LTCC) film. This innovative material offers superior thermal conductivity, flexibility, and compatibility with various substrates, making it an ideal choice for applications ranging from power electronics to microelectronics.

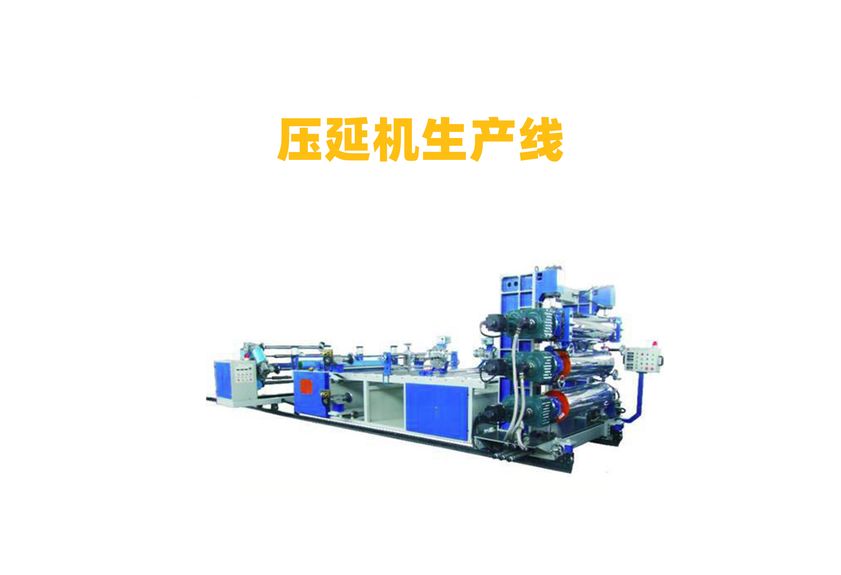

One of the key components in the production process of LTCC films is the liquid thermal conductive silicone rolling machine. This machine plays a crucial role in shaping and applying the liquid silicone into thin films on various substrates. It is essential to understand how this machine works and its capabilities to fully appreciate the importance of LTCC films in modern technology.

The liquid thermal conductive silicone rolling machine consists of several key components, including a roller assembly, a heating system, a cooling system, and a control system. The roller assembly is responsible for applying pressure and shape the silicone onto the substrate. It is made up of multiple rollers that rotate at different speeds to achieve uniform application of the silicone. The heating system heats the silicone to a specific temperature, while the cooling system maintains the temperature within a narrow range to prevent degradation of the material.

The control system is responsible for monitoring and adjusting the parameters of the machine to ensure consistent results. It includes sensors that measure the thickness, width, and length of the silicone film, as well as other relevant parameters. The control system then sends signals to the motors and other components of the machine to adjust the speed and pressure accordingly.

The liquid thermal conductive silicone rolling machine has several advantages over traditional methods of producing LTCC films. Firstly, it allows for precise control of the thickness and width of the silicone film, which is critical for achieving optimal performance in electronic devices. Secondly, it reduces waste by minimizing the amount of silicone that is wasted during the process. Finally, it improves productivity by reducing the time required to produce each batch of silicone film.

In conclusion, the liquid thermal conductive silicone rolling machine is a vital component in the production process of LTCC films. Its ability to apply the silicone onto various substrates with precision and efficiency makes it an essential tool for the advancement of electronics and aerospace technology. As technology continues to evolve, we can expect to see even more innovative solutions like this rolling machine that will revolutionize the way we produce high-performance thermal interface materials.