The Role of Mass Production Type Mixing Machines in the Manufacturing Industry

In the manufacturing industry, there is a constant demand for efficient and reliable machinery to process raw materials into finished products. One such machine that plays a crucial role in this process is the mass production type mixing machine. These machines are designed to handle large quantities of material at high speeds, making them ideal for industries such as food processing, chemical manufacturing, and plastics production.

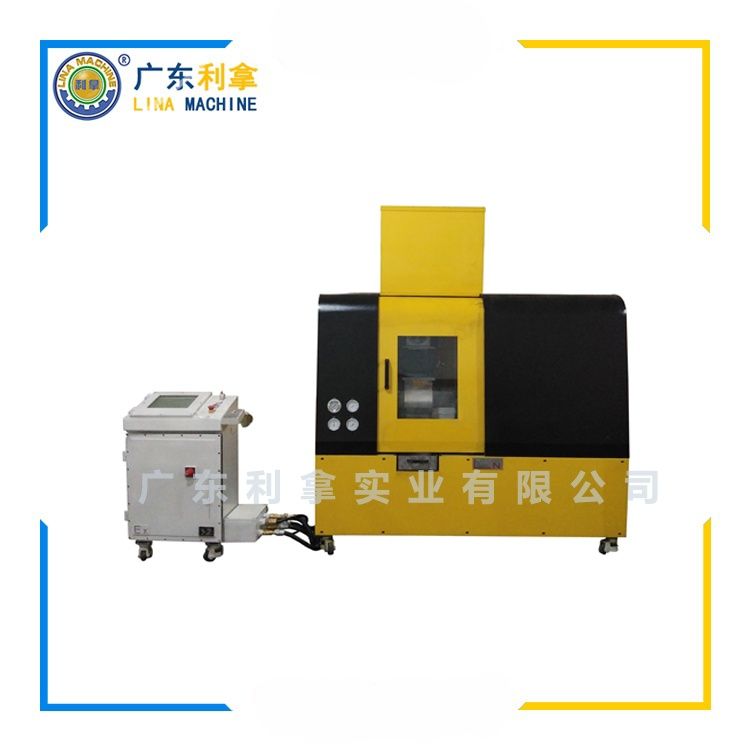

The key features of a mass production type mixing machine include its ability to mix multiple batches simultaneously, its high-speed rotational capability, and its ability to handle a wide range of materials. These machines are typically equipped with advanced sensors and control systems that allow for precise temperature regulation and mixing efficiency.

One of the benefits of using mass production type mixing machines is their ability to save time and labor costs. By reducing the need for manual labor and minimizing errors, these machines can increase productivity and reduce downtime. Additionally, they can help to improve product quality by ensuring that all batches are mixed consistently and accurately.

Another advantage of mass production type mixing machines is their flexibility. These machines can be customized to meet specific needs and requirements, whether they be for different types of materials or different levels of mixing intensity. This makes them ideal for use in a variety of industries, from pharmaceuticals to automotive parts.

In conclusion, mass production type mixing machines play a vital role in the manufacturing industry by providing efficient and reliable machinery for processing raw materials into finished products. With their ability to handle large quantities of material at high speeds and their ability to customize to specific needs, these machines are essential tools for any industry looking to improve productivity and product quality.