Understanding the Application of Absorber Material Rolling Machines in Advanced Manufacturing

In the realm of advanced manufacturing, the development of innovative materials and processes is crucial for enhancing efficiency and reducing costs. One such area that has seen significant advancements is the use of absorber material rolling machines, which play a vital role in the production of high-performance absorbers for various applications, including automotive, aerospace, and electronics.

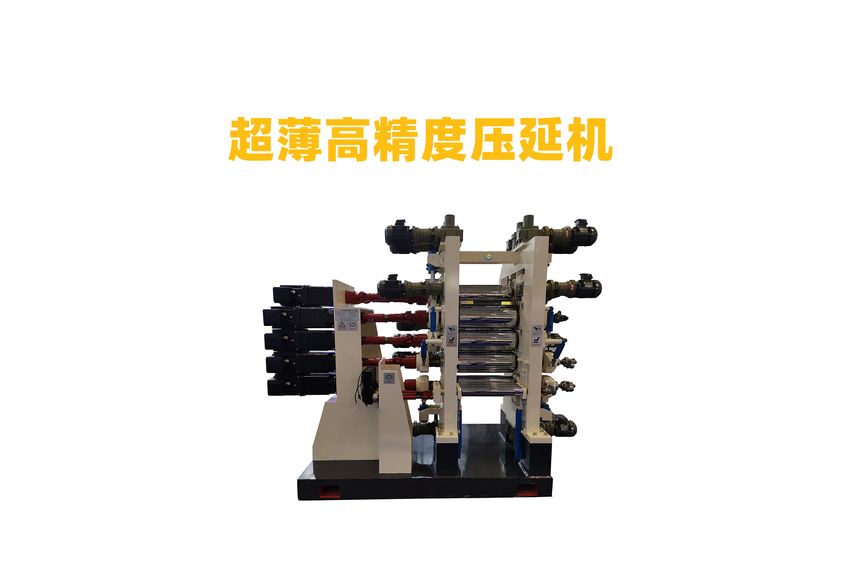

The absorber material rolling machine is a sophisticated piece of machinery designed to process absorber materials into their final form. This process involves several key steps, including preheating, rolling, cooling, and post-treatment. The machine's ability to precisely control these steps allows for consistent quality and performance across different batches.

One of the key benefits of using an absorber material rolling machine is its ability to produce high-quality absorbers with minimal waste. By utilizing advanced sensors and algorithms, the machine can detect any defects or irregularities in the material during the processing stage, allowing for immediate adjustments to improve the final product.

Another advantage of this technology is its ability to reduce downtime and increase productivity. With the ability to process large volumes of material quickly and efficiently, manufacturers can meet their production schedules without compromising on quality. Additionally, the machine's automated features make it easy to scale up production as needed, further enhancing flexibility and scalability.

In conclusion, the use of absorber material rolling machines in advanced manufacturing is essential for producing high-quality absorbers with consistent performance. By leveraging the latest technological advancements, manufacturers can optimize their operations and drive innovation in the industry.