Understanding the Thermal Conductive Silicone Roll Press Line

The thermal conductive silicone roll press line is an essential component in the manufacturing process of electronic devices, such as heat sinks and thermal interface materials. This article will provide a detailed introduction to this line, including its design, functions, and application scenarios.

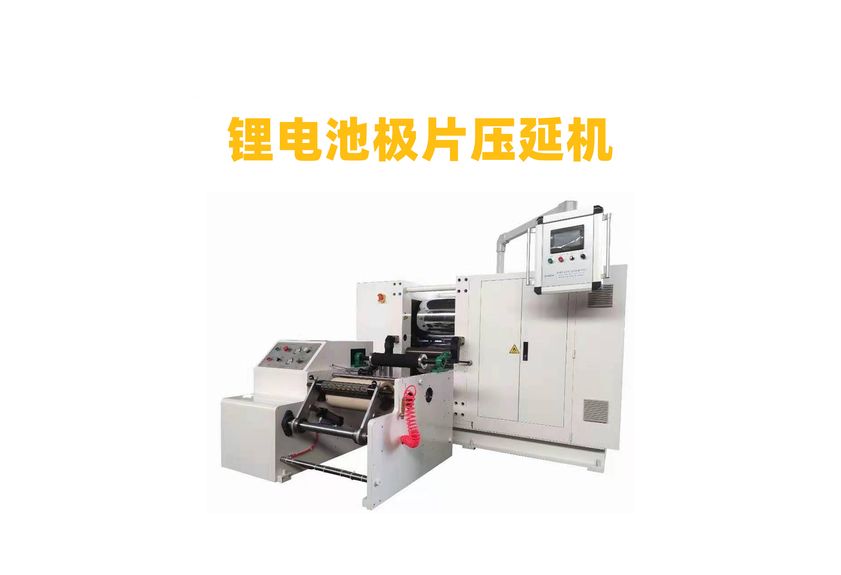

Firstly, the design of the thermal conductive silicone roll press line is crucial for its performance. It typically consists of several key components, including the roller, pressure plate, and cooling system. The roller is made of high-quality thermal conductive silicone material, which can effectively transfer heat from the workpiece to the cooling system. The pressure plate is used to apply pressure on the workpiece during the pressing process, ensuring that the workpiece is evenly pressed and does not deform. The cooling system is designed to dissipate heat generated by the workpiece during the pressing process, preventing overheating and maintaining the stability of the production line.

Secondly, the functions of the thermal conductive silicone roll press line are diverse. Firstly, it can be used to produce various types of thermal conductive silicone products, such as heat sinks, thermal interface materials, and heat dissipation plates. Secondly, it can also be used to process other materials, such as plastics and metals, to improve their thermal conductivity and performance. Thirdly, it can be used to automate the entire production process, reducing labor costs and improving production efficiency.

Finally, the application scenarios of the thermal conductive silicone roll press line are extensive. It can be used in the manufacturing of electronic devices, such as computers, mobile phones, and gaming consoles, to improve their heat dissipation performance and enhance user experience. It can also be used in the manufacturing of industrial equipment, such as fans and pumps, to improve their efficiency and reduce energy consumption. Additionally, it can be used in the manufacturing of automotive parts, such as engine blocks and transmissions, to improve their durability and reliability.