The Art of Wood Pellet Making Machines

In the world of sustainable energy, wood pellet machines play a crucial role in transforming renewable resources into usable fuel. These machines are designed to process compressed wood chips into pellets that can be used as a substitute for fossil fuels in various applications, such as heating and cooking.

The first step in creating wood pellets is the selection of the right type of wood. Different woods have varying levels of moisture content, which affects the quality and consistency of the pellets produced. Therefore, it's essential to choose wood that has been dried properly to ensure uniformity in the final product.

Once the wood is selected, it's processed through a series of steps using a wood pellet making machine. The first step involves shredding the wood into small pieces, which are then passed through a screen to remove any larger particles. This process is known as chipping or chopping.

Next, the chips are mixed with a binder, usually a combination of oil and water, to create a paste-like consistency. This mixture helps bind the wood particles together and prevent them from clumping during the pelletizing process.

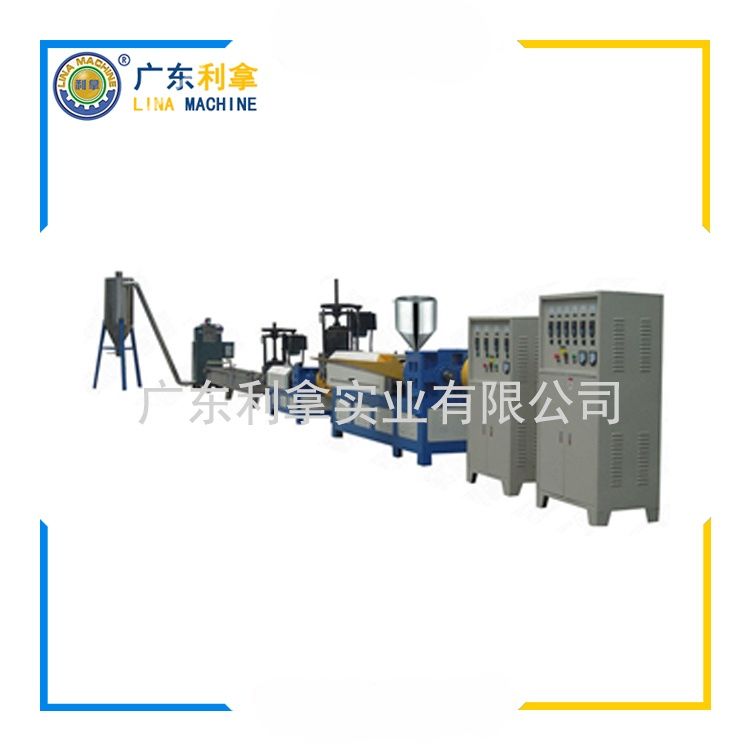

The mixture is then fed into a pelletizing machine, which uses high-pressure air to compress the wood particles into pellets. The size and shape of the pellets depend on the specific machine being used and the parameters set by the manufacturer.

After the pellets are formed, they are cooled and packaged for storage or transportation. Some machines may also incorporate additional features, such as a heat exchanger or a drying system, to further improve the quality of the pellets.

In conclusion, wood pellet machines are an essential tool for converting renewable resources into usable fuel. By following proper procedures and selecting the right wood, these machines can produce high-quality pellets that can be used in various industries. As demand for sustainable energy continues to grow, the importance of wood pellet machines will only increase.