The Integration of Scarfing Press Machinery in the Production Line

In the realm of industrial manufacturing, the scarfing press machine is a crucial tool that plays a significant role in the production process. This article will delve into the intricate details of the scarfing press machine's integration into the production line, highlighting its significance and effectiveness in enhancing productivity and quality control.

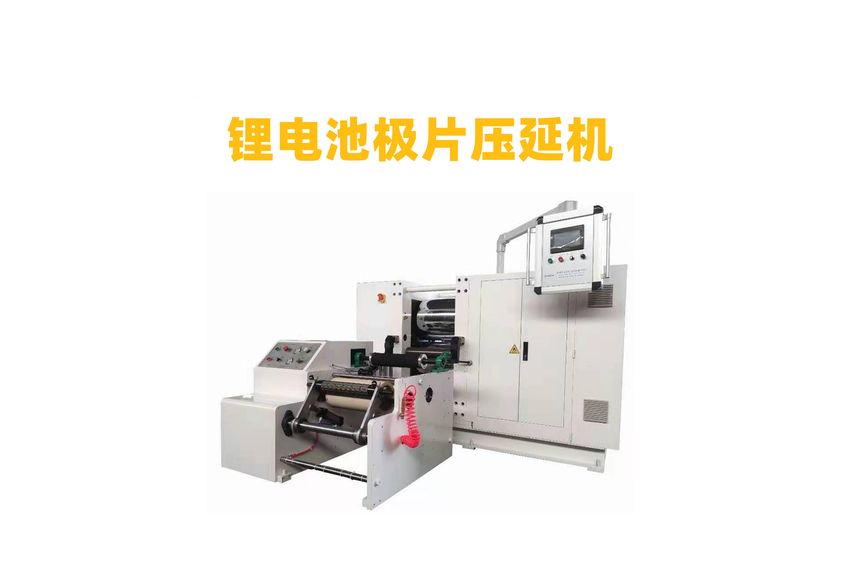

At the heart of this machine lies its ability to precisely and efficiently apply pressure to raw materials, such as metal sheets or plastic films, to create a smooth surface finish. This process is known as 'scarfing', which involves pressing the material against a rotating drum with a high-pressure roller. The resulting scarfed material is then ready for further processing or assembly.

The scarfing press machine is an essential component of any modern manufacturing facility, offering several advantages over traditional manual methods. Firstly, it significantly reduces labor costs by eliminating the need for skilled workers to manually apply pressure and shape the material. This not only saves time but also ensures consistent results every time, minimizing waste and errors.

Secondly, the scarfing press machine enhances product quality by providing a uniform and smooth surface finish. This is particularly important in industries where the appearance of the finished product is critical, such as automotive or electronics manufacturing. A well-scarfed surface can reduce scratches, dents, and other imperfections, improving the overall aesthetic appeal and durability of the product.

Moreover, the scarfing press machine offers flexibility in terms of material types and thicknesses. It can handle a wide range of materials, including metals, plastics, and composites, and can adjust the pressure and speed according to the specific requirements of each product. This makes it ideal for mass production lines where consistency is key.

In addition to these technical benefits, the scarfing press machine also contributes to environmental sustainability by reducing energy consumption and emissions. By using less power and generating less heat, it helps to minimize the carbon footprint associated with traditional manufacturing processes.

In conclusion, the integration of the scarfing press machine into the production line has revolutionized the way we manufacture products. Its precision, efficiency, and consistency have made it an essential tool for modern industrial operations. As technology continues to advance, we can expect to see even more innovative applications of this versatile machine in various industries.