The Art of the Five-Roll Rolling Mill

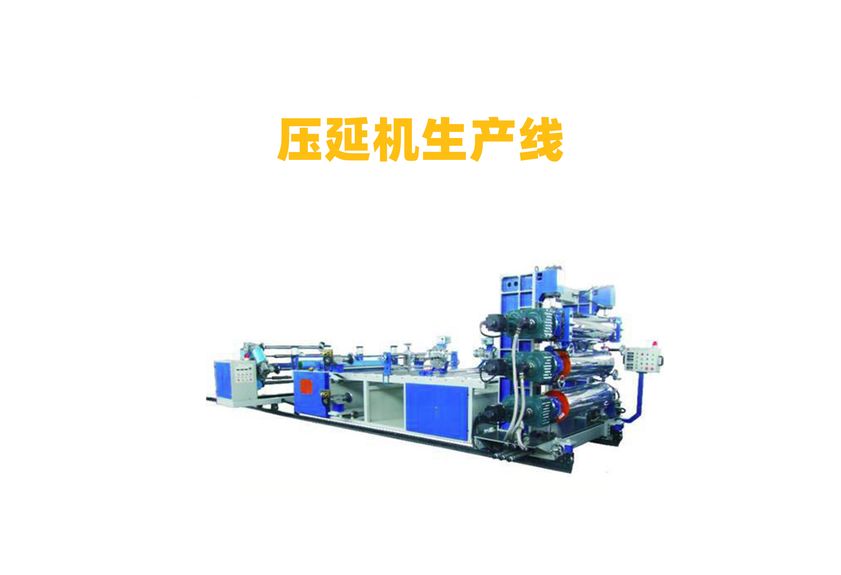

The five-roll rolling mill is a crucial tool in the manufacturing industry, particularly in the production of sheet metal products. This machine uses five rollers to compress and shape the raw material into the desired final product. It is widely used in industries such as automotive, aerospace, and construction, where its efficiency and precision are essential for quality control.

One of the key features of a five-roll rolling mill is its ability to handle a wide range of materials, including steel, aluminum, and copper. The machine's design allows for precise adjustment of the pressure and speed of the rollers, which can be adjusted to meet the specific needs of each material. This flexibility makes it an ideal choice for companies that need to produce a variety of products with different specifications.

Another advantage of the five-roll rolling mill is its ability to produce high-quality products. Thanks to its advanced technology, the machine can achieve uniform thickness and smooth surface finishes, which are critical for many applications. Additionally, the machine's precision components ensure that the finished product meets or exceeds industry standards.

In terms of maintenance, the five-roll rolling mill requires regular inspection and servicing to keep it running smoothly. However, with proper care and attention, this machine can last for many years, providing reliable performance and cost savings for businesses.

1. Five-roll rolling mill

2. Manufacturing industry

3. Sheet metal products

4. Precision components

5. Industry standards

6. Maintenance

7. Cost savings

8. Industry application

9. Advanced technology

10. Uniform thickness

11. Smooth surface finishes

12. Industry standards

This article provides an in-depth overview of the five-roll rolling mill, highlighting its importance in the manufacturing industry and its various applications. We explore the machine's unique features, including its ability to handle a wide range of materials and produce high-quality products. We also discuss the importance of maintaining the machine and the benefits of using it in industries such as automotive, aerospace, and construction. By understanding the capabilities and benefits of this versatile machine, businesses can make informed decisions about their production processes and optimize their operations.