The Integration of EVA, TPR, and PVC Pulping Lines

In the realm of polymer processing, the integration of different types of plastics into a single production line is a common practice. This article will delve into the intricacies of integrating an EVA (Ethylene Vinyl Acetate), TPR (Thermoplastic Rubber), and PVC (Polyvinyl Chloride) pulping line.

The first step in this process is to ensure that the raw materials are of high quality and consistent in their properties. This includes selecting appropriate equipment for each type of plastic, as well as ensuring that the temperature and pressure settings are optimal for each material.

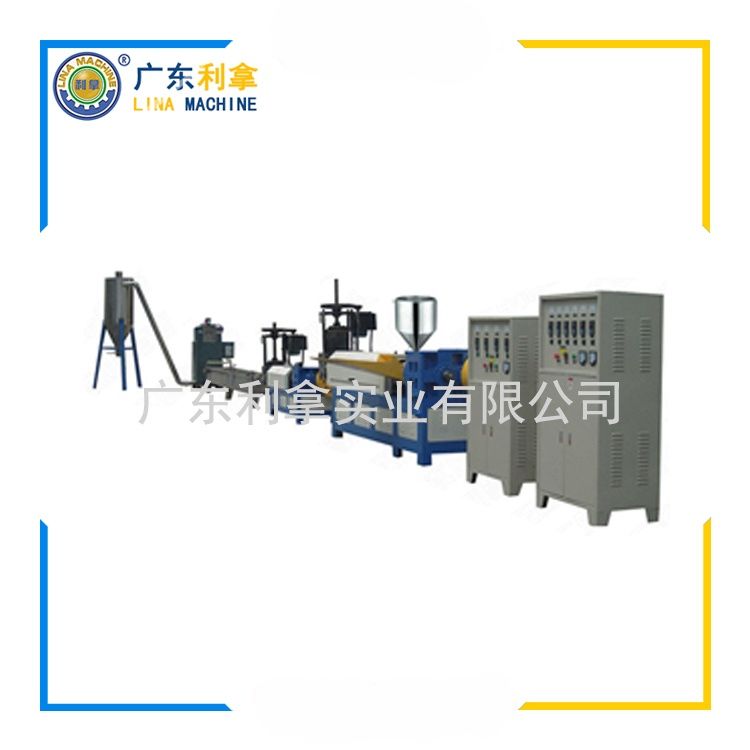

Once the raw materials have been processed, they are then fed into the pulping line. This line uses specialized equipment to break down the plastic into smaller particles, which can be further processed into various forms such as films, sheets, or injection molded products.

One of the key challenges in integrating these different types of plastics is maintaining consistency in the final product's properties. To achieve this, the pulping line must be carefully designed and optimized to ensure that all components work together seamlessly.

Another important aspect of this integration is safety. With different types of plastics being processed in the same facility, it is crucial to ensure that all safety protocols are followed, including proper ventilation, fire prevention measures, and emergency response plans.

Finally, the integration of EVA, TPR, and PVC pulping lines requires a deep understanding of each material's characteristics and how they interact with one another. This knowledge is essential for achieving optimal results and minimizing any potential issues that may arise during the production process.

1. EVA Pulp Line

2. TPR Pulp Line

3. PVC Pulp Line

4. Plastic Processing

5. Integrated Production Line

This article provides an in-depth look at the integration of EVA, TPR, and PVC pulping lines into a single production facility. It covers the challenges and benefits of integrating these different types of plastics, as well as the importance of safety and understanding each material's characteristics. By following these guidelines, businesses can optimize their production processes and achieve maximum efficiency and quality output.