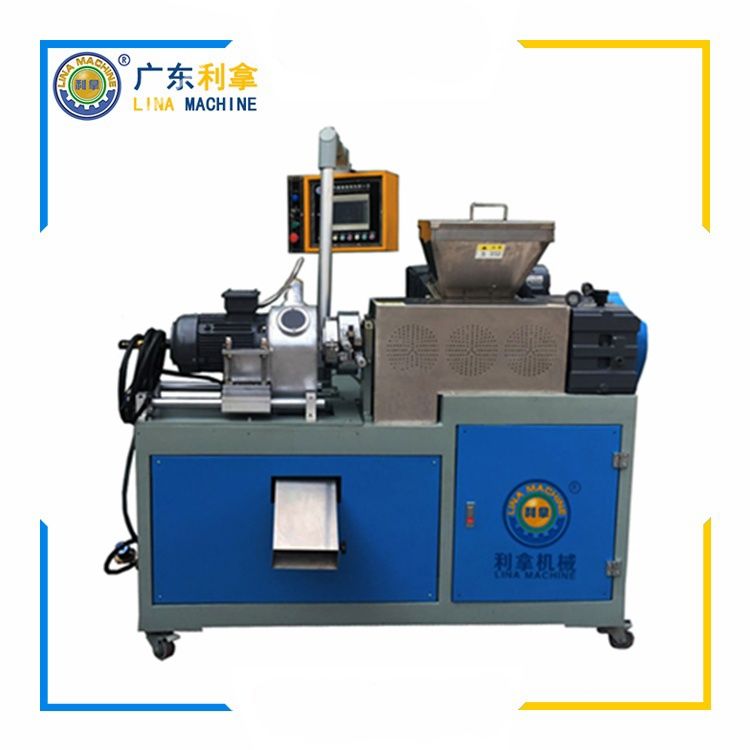

The Double-Screw Extrusion Spraying Machine

The double-screw extruder is a versatile and efficient tool used in the production of various plastic materials. It is a key component in the extrusion process, where molten polymers are forced through a die to form solid pellets or granules. This machine is widely used in the manufacturing industry for its ability to produce high-quality products with consistent size and shape.

The working principle of a double-screw extruder involves two rotating screws that push the molten polymer through the die. As the screws move, they create a continuous flow of material, which is then forced out of the die and into a cooling chamber. Here, the material cools and solidifies, forming the desired product. The final product is then collected and packaged for further use.

One of the key advantages of using a double-screw extruder is its ability to produce uniform and consistent products. The machine's precise control over the temperature and pressure allows for accurate melting and solidification, resulting in products with a high degree of quality. Additionally, the machine's compact design makes it easy to transport and install, making it ideal for small-scale operations.

In addition to its practical applications, the double-screw extruder also has a significant impact on the environment. By reducing waste and minimizing energy consumption, this machine helps to reduce greenhouse gas emissions and promote sustainable manufacturing practices. Furthermore, its efficient use of resources means that it can help to reduce costs and improve profitability for businesses operating in the plastics industry.

1. Double-Screw Extruder

2. Plastic Production

3. Quality Products

4. Environmental Impact

5. Sustainable Manufacturing

The double-screw extruder is an essential tool in the plastics industry, capable of producing high-quality products with consistent size and shape. Its unique ability to produce uniform and consistent products sets it apart from other extrusion machines, making it a valuable asset for any manufacturing operation. In addition to its practical applications, the double-screw extruder also has a significant impact on the environment, promoting sustainable manufacturing practices and reducing greenhouse gas emissions. With its efficient use of resources and cost-effectiveness, this machine is an ideal choice for businesses looking to improve their bottom line while minimizing their environmental footprint.