Understanding the Benefits of Calcium Powder Compounding Granulators

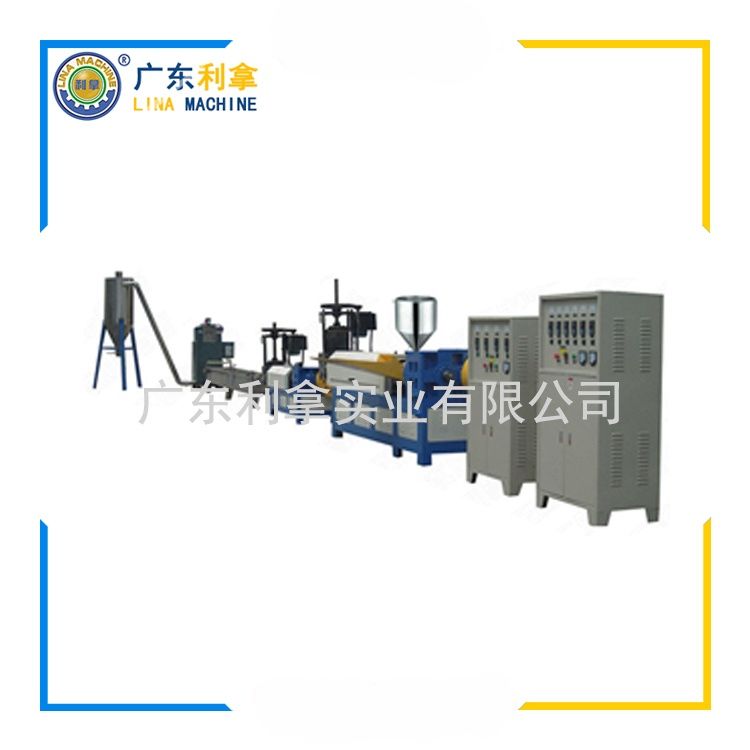

In the realm of polymer processing, the use of calcium powder compounding granulators is a common practice that has gained significant attention in recent years. These machines are designed to efficiently mix and granulate various types of calcium compounds, including calcium carbonate, calcium hydroxide, and calcium nitrate, which are crucial for various industrial applications such as pharmaceuticals, food additives, and construction materials.

One of the primary benefits of using calcium powder compounding granulators is their ability to produce high-quality granulated products with consistent size and shape. These machines use advanced technology to ensure that the calcium compounds are evenly mixed and granulated, resulting in a product that is free from impurities and has a uniform texture. This not only improves the quality of the final product but also reduces waste and increases efficiency.

Another advantage of these machines is their flexibility in terms of material handling. They can handle a wide range of calcium compounds, including those with different particle sizes and shapes. This makes them ideal for industries that require customized granulation processes, such as pharmaceuticals or food additives. Additionally, these machines are often equipped with automation features, allowing operators to easily control the process and monitor the output quality throughout the manufacturing process.

In addition to their technical advantages, calcium powder compounding granulators also have environmental benefits. By producing granulated products with a consistent size and shape, they reduce the amount of waste generated during the manufacturing process. This not only saves resources but also helps to minimize the environmental impact of the production process.

In conclusion, calcium powder compounding granulators are an essential tool for industries that require efficient and high-quality granulation processes. Their ability to produce high-quality granulated products with consistent size and shape, along with their flexibility in material handling and automation features, make them a preferred choice for many businesses. As the demand for these machines continues to grow, it is clear that they will continue to play a vital role in the future of polymer processing.