PCM相变化导热硅胶压延机技术解析

In the field of electronics and information technology, the application of PCM (Phase Change Material) thermal interface materials has become increasingly important. These materials have unique properties such as excellent thermal conductivity, low thermal resistance, and high reliability, making them ideal for use in heat dissipation and thermal management applications. One of the key technologies used to manufacture these materials is the PCM phase change thermal conductive adhesive vulcanization process, which involves using a specialized machine called a PCM phase change thermal conductive adhesive vulcanization machine.

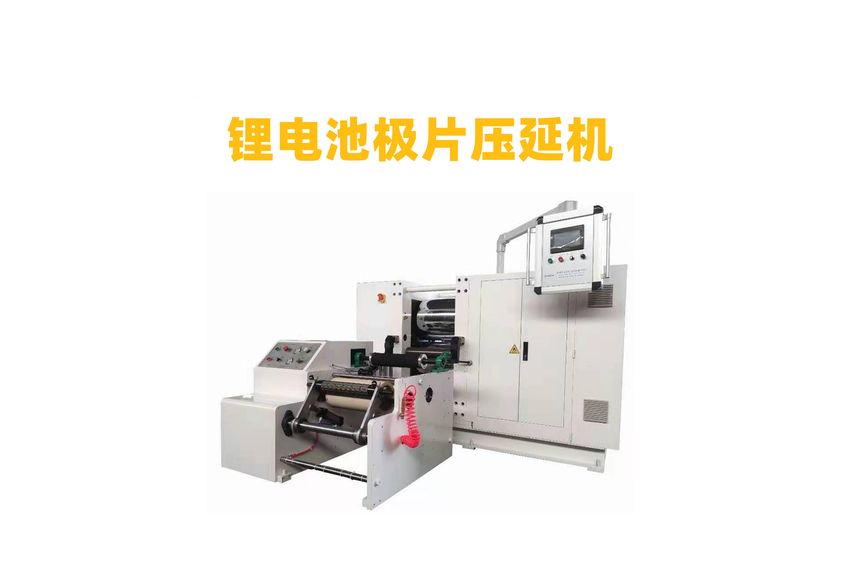

The PCM phase change thermal conductive adhesive vulcanization machine is a highly sophisticated equipment designed to produce PCM thermal interface materials with specific properties. It consists of several key components, including a heating system, a cooling system, a pressure control system, and a monitoring system. The heating system is responsible for providing heat energy to the PCM material during the vulcanization process, while the cooling system helps maintain the temperature within a controlled range. The pressure control system ensures that the pressure inside the machine remains stable during the vulcanization process, while the monitoring system continuously monitors the progress of the process and alerts operators if any issues arise.

One of the main advantages of using the PCM phase change thermal conductive adhesive vulcanization machine is its ability to produce PCM materials with high thermal conductivity and low thermal resistance. This makes it possible to achieve better heat dissipation and thermal management performance in electronic devices, such as CPUs, memory modules, and motherboards. Additionally, the machine's precision control system allows for precise adjustment of the parameters during the vulcanization process, ensuring consistent quality and repeatability in the final product.

In conclusion, the PCM phase change thermal conductive adhesive vulcanization machine is an essential tool for producing high-quality PCM thermal interface materials. Its advanced technology and precise control capabilities make it an ideal choice for manufacturers looking to improve their products' thermal performance and reliability. As the demand for these materials continues to grow, the importance of this machine in the industry cannot be overstated.