The Two-Roll Mill: A Detailed Guide to Its Function and Applications

The two-roll mill, also known as a twin-roll mill, is a crucial piece of machinery in the rubber industry. It is a type of extruder used for mixing and shaping rubber compounds, which are then processed into various products such as tires, hoses, and other automotive components. In this article, we will delve into the basic functions of the two-roll mill, its working principles, and its applications in the rubber manufacturing process.

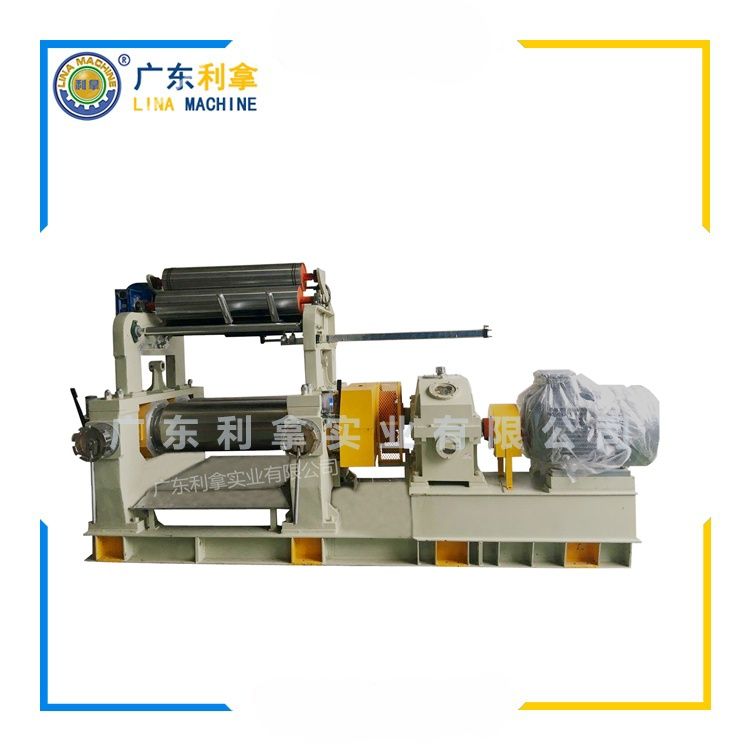

Firstly, let's understand what a two-roll mill is. It is a machine that consists of two rotating rollers, each with a diameter of around 10 inches. These rollers are separated by a gap of about 2-3 inches, allowing the rubber compound to flow between them. The rollers are driven by a motor, which rotates at a speed of around 500 revolutions per minute (rpm). This rotational motion causes the rubber compound to be forced through the gap between the rollers, resulting in a homogeneous mixture.

Now, let's discuss the working principles of the two-roll mill. When the rollers start moving, they create a high shear rate, which helps to break down the rubber molecules into smaller particles. This process is known as "breaking" or "kneading." As the rubber compound moves through the gap between the rollers, it is further mixed and kneaded, resulting in a more uniform and consistent product. The two-roll mill is designed to handle a wide range of rubber compounds, including natural latex, synthetic latex, and blends of different materials.

In terms of applications, the two-roll mill is essential in the rubber manufacturing process. It is used to produce tires, hoses, gloves, and other automotive parts made from rubber compounds. For example, tires are made by extruding a rubber compound through the two-roll mill and then curing it in a vulcanizing oven. The resulting tire has a smooth surface and excellent durability due to the even distribution of rubber molecules. Similarly, hoses are produced by extruding a rubber compound through the two-roll mill and then stretching it to form a seamless tube.

Another application of the two-roll mill is in the production of elastomeric films and sheets. These products are used in various industries, such as packaging, construction, and automotive. The two-roll mill is capable of producing films with thicknesses ranging from 0.001 inch to 0.04 inches, depending on the specific requirements of the end product.

In conclusion, the two-roll mill is a crucial tool in the rubber manufacturing process. It plays a vital role in breaking down rubber compounds into a homogeneous mixture and kneading them into a more uniform product. Its wide range of applications makes it an essential piece of machinery in the automotive and industrial sectors. By understanding its working principles and applications, manufacturers can optimize their production processes and achieve better results.