The Metal Mixing Machine: A Revolutionary Tool for the Manufacturing Industry

The metal mixing machine is a vital tool in the manufacturing industry, revolutionizing the way materials are processed and blended. At its core, this machine utilizes high-speed rotation to mix various metals together, creating a homogeneous mixture that is then compacted into a solid form. This process is essential in industries such as automotive, aerospace, and electronics, where precise tolerances and consistent quality are crucial.

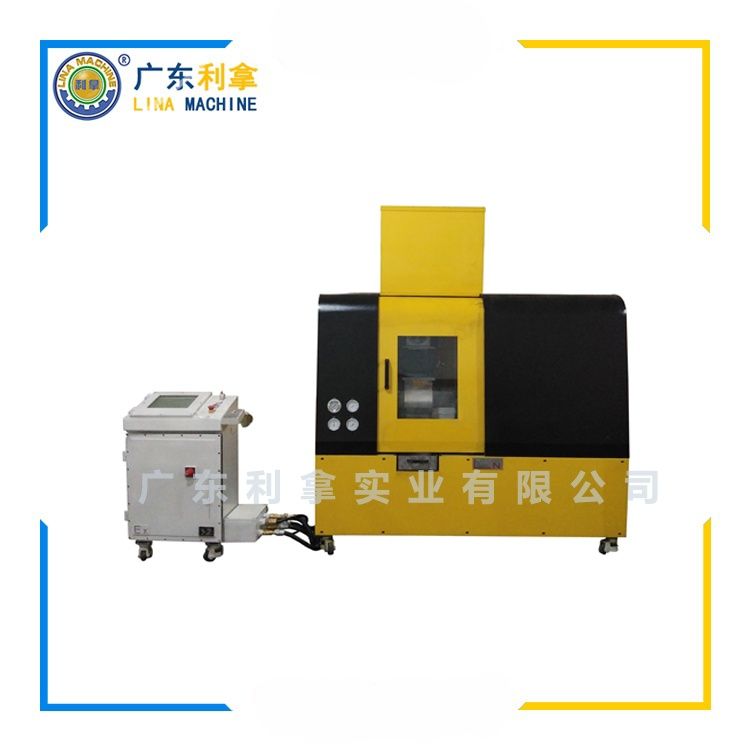

One of the key features of a metal mixing machine is its ability to handle a wide range of materials, including steel, aluminum, and copper. The machine's design allows for easy access to the mixing chamber, making it easy to add or remove materials as needed. Additionally, many modern metal mixing machines come with advanced sensors that monitor the temperature and pressure inside the chamber, ensuring that the mixture is always at the optimal temperature and pressure for optimal mixing.

Another advantage of metal mixing machines is their efficiency. By using high-speed rotation, these machines can produce a large amount of material in a short amount of time, saving both labor and resources. This efficiency not only benefits the manufacturing process but also reduces costs overall.

In addition to their practical applications, metal mixing machines also have a significant impact on the environment. By reducing the need for manual labor and minimizing waste, these machines help to reduce greenhouse gas emissions and other pollutants associated with traditional manufacturing processes.

As the demand for precision and consistency continues to grow, the importance of metal mixing machines in the manufacturing industry cannot be overstated. These machines are not just tools; they are a critical component of the future of manufacturing, enabling companies to produce products that meet the highest standards of quality and reliability.