The Role of Multifunctional Compounding and Granulation Machines in the Manufacturing Industry

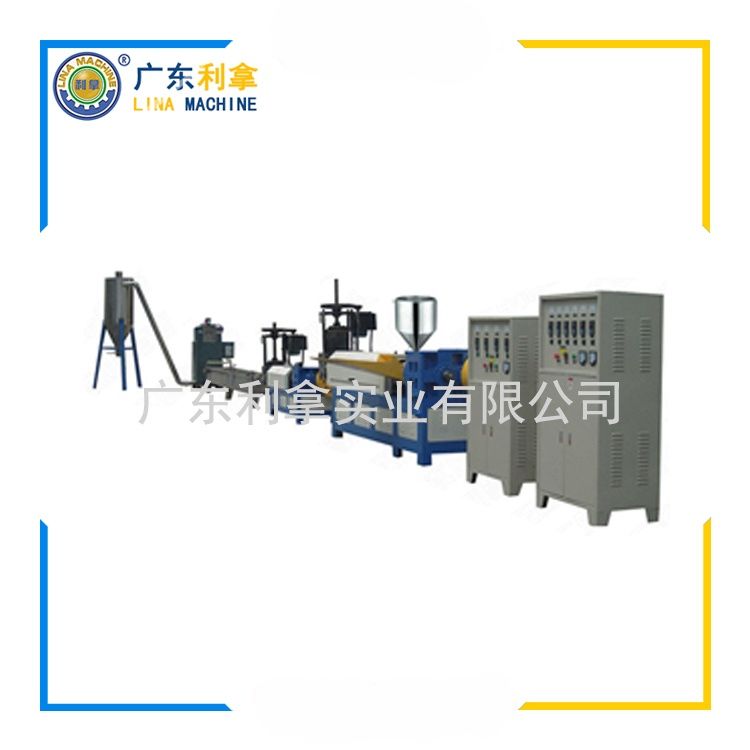

In the manufacturing industry, the process of compounding and granulating raw materials is a crucial step that transforms them into finished products. This process involves mixing, blending, and compacting various components to create a uniform and consistent product. However, traditional methods of compounding and granulation often require multiple machines and laborious steps, which can be time-consuming and costly. That's where multifunctional compounding and granulation machines come into play. These advanced machines are designed to perform multiple functions simultaneously, reducing downtime, labor costs, and production time.

One example of a multifunctional compounding and granulation machine is the X-ray Compounding Granulator. This machine combines the functions of a compounding machine and a granulator, allowing for the mixing and granulation of different materials in one go. It features a high-speed rotor that rotates at up to 10,000 RPM, ensuring even mixing and compaction of the ingredients. Additionally, the machine has a built-in cooling system to prevent overheating during operation, which is essential for maintaining the quality of the final product.

Another example is the Automatic Compounding Granulator, which uses a combination of screw and roller techniques to mix and granulate materials. The machine has a variable speed control system that allows for precise adjustment of the mixing and granulating speeds, ensuring consistency in the final product. The machine also features a dust collection system to minimize airborne particles, protecting the operator from harmful fumes.

The benefits of using multifunctional compounding and granulation machines are numerous. They reduce downtime by eliminating the need for separate machines for mixing and granulating, resulting in faster production times. Labor costs are also reduced, as operators can perform multiple functions simultaneously, saving time and increasing efficiency. Furthermore, the use of advanced technology in these machines ensures higher quality products, as they are designed to handle a wide range of materials and produce consistent results.

In conclusion, multifunctional compounding and granulation machines have revolutionized the manufacturing industry by providing efficient and cost-effective solutions for mixing and granulating raw materials. By leveraging the latest technological advancements, manufacturers can improve their productivity, reduce waste, and ultimately increase profitability.