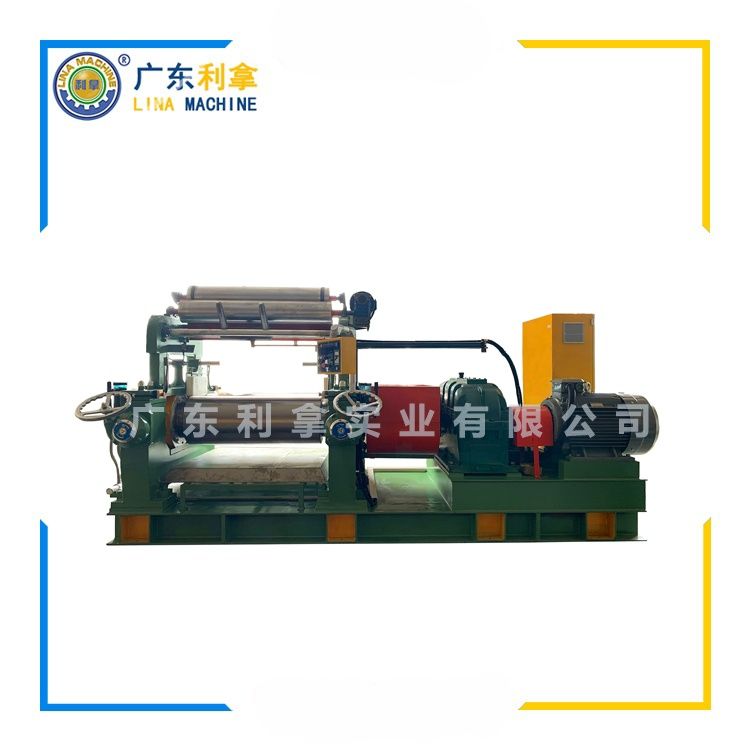

Experimental Open Roller Mills: Revolutionizing the Manufacturing Process

Open roll mills, also known as experimental open roller mills, are a revolutionary tool in the manufacturing industry. These machines have been designed to simulate real-world conditions and provide an accurate representation of industrial processes. They are used for various purposes, including testing new materials, developing new production techniques, and enhancing existing ones.

One of the key features of open roll mills is their ability to simulate different types of material handling and processing. This includes the use of rollers that can be adjusted to mimic the physical properties of different materials. For example, some open roll mills use rollers made from steel or aluminum, while others may use ceramic or plastic materials. This allows for a more accurate simulation of the process and helps to identify any potential issues before they become a problem in the actual production line.

Another advantage of open roll mills is their ability to monitor and control the temperature and pressure levels throughout the process. This is important because many manufacturing processes require precise temperature and pressure control to ensure the quality and consistency of the final product. By using open roll mills, manufacturers can easily monitor these parameters and make adjustments as needed.

In addition to their technical advantages, open roll mills also offer cost savings. Since they can be used for a variety of applications, manufacturers can save money by investing in one machine rather than multiple specialized machines. This not only reduces equipment costs but also streamlines the overall process, making it easier to manage and maintain.

Overall, experimental open roll mills are a valuable tool for manufacturers looking to improve their production processes and reduce costs. With their ability to simulate real-world conditions and provide accurate data, they are becoming increasingly popular in industries across the globe.