Understanding Rubber Masterbatch Granulators

In the realm of polymer processing, masterbatch granulators play a crucial role in the production process. These machines are designed to blend and granulate various additives into a uniform mixture that can be used as a base for various plastics and rubber products. The efficiency and quality of these granulators have a direct impact on the overall performance of the end product. In this article, we will explore the different types of rubber masterbatch granulators available in the market, their features, and how they can benefit your production process.

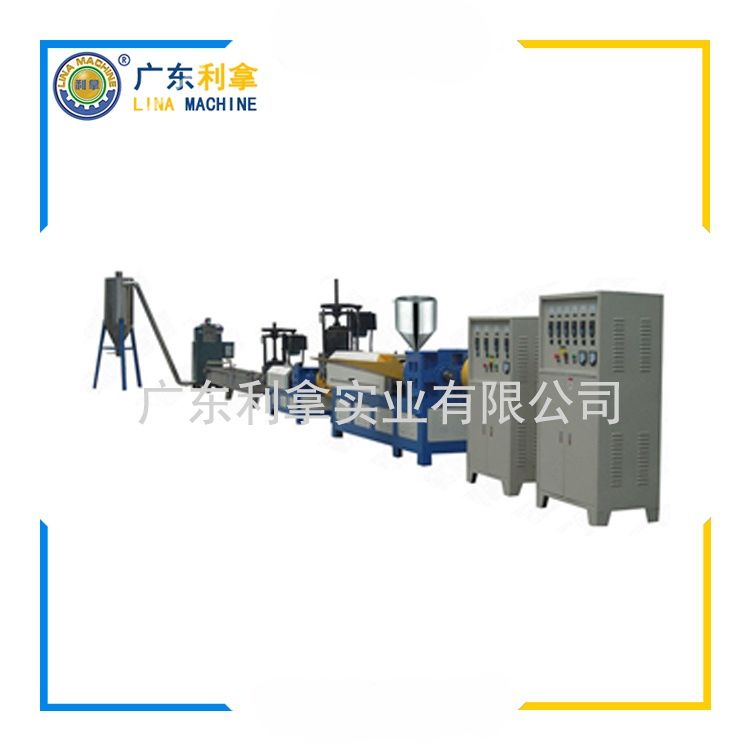

One of the most popular types of rubber masterbatch granulators is the twin-screw extruder. This machine uses two parallel screws to mix and granulate the additives into a homogeneous mixture. The twin-screw extruder has several advantages over other types of granulators, such as its ability to handle a wide range of additives and its flexibility in adjusting the mixing and granulating conditions. Additionally, the twin-screw extruder can produce high-quality products with minimal waste.

Another type of rubber masterbatch granulator is the rotary drum granulator. This machine uses a rotating drum to mix and granulate the additives into a uniform mixture. The rotary drum granulator is ideal for small-scale production and can be easily customized to meet specific needs. However, it may not be as efficient as other granulators in terms of mixing speed and product quality.

When selecting a rubber masterbatch granulator, it is essential to consider factors such as the size of the production line, the type of additives being processed, and the desired product quality. A well-chosen granulator can significantly improve the efficiency and quality of your production process.

In conclusion, masterbatch granulators play a vital role in the production of various plastics and rubber products. By understanding the different types of granulators available and their features, you can choose the right one for your specific needs. With the right equipment, you can achieve optimal results and increase productivity while minimizing waste.