The Role of Pressing and Rolling Mills in the Manufacturing Industry

The manufacturing industry is a complex and diverse field that requires the use of various machinery to produce products. One such machine is the pressing and rolling mill, which plays a crucial role in the production process. In this article, we will explore the different types of pressing and rolling mills, their functions, and how they contribute to the overall manufacturing process.

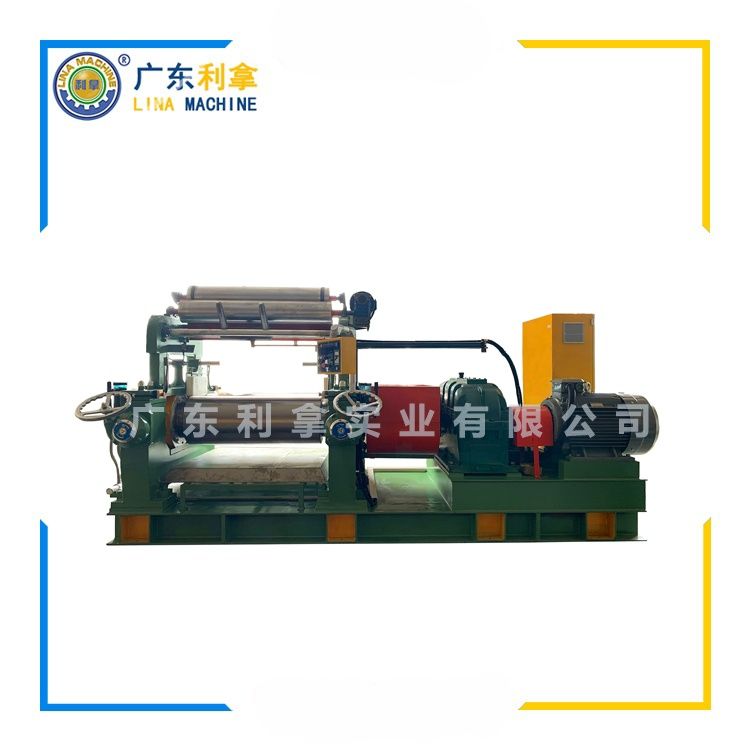

Firstly, let us understand what a pressing and rolling mill is. It is a type of machine used for shaping materials into desired shapes by applying pressure and heat. This process is commonly used in the manufacturing industry to produce sheet metal, pipes, and other structural components.

There are two main types of pressing and rolling mills: rotary presses and flat presses. Rotary presses are designed to rotate around a central axis, while flat presses are stationary machines that apply pressure to the material being processed.

Rotary presses are commonly used for sheet metal processing, where the material is fed into the machine and then pressed against a heated die. This process results in the formation of a uniform sheet of metal, which can be further processed to meet specific requirements.

Flat presses, on the other hand, are used for pipe processing, where the material is fed into the machine and then pressed against a heated die. This process results in the formation of a seamless pipe with a uniform thickness and diameter.

In addition to their primary function, pressing and rolling mills also have several advantages over other manufacturing processes. For example, they can produce high-quality products with minimal waste, as the material is only removed from the machine when it has been successfully formed. Additionally, these machines are often more efficient than other methods of producing similar products, as they require less energy and time to complete the process.

However, like any machine, there are some limitations to using pressing and rolling mills. For example, they may not be suitable for certain materials or applications, and they may require specialized equipment and expertise to operate effectively. However, with proper maintenance and regular inspections, these machines can continue to provide valuable contributions to the manufacturing industry for many years to come.

In conclusion, the pressing and rolling mill is an essential piece of machinery in the manufacturing industry. Its ability to shape materials into desired shapes using pressure and heat makes it a valuable tool for producers looking to produce high-quality products quickly and efficiently. By understanding the different types of pressing and rolling mills and their functions, manufacturers can make informed decisions about which machines are best suited for their specific needs.