The Role of Granule Rolling Machines in the Manufacturing Industry

The manufacturing industry is a complex and diverse field that requires the use of various machinery to produce high-quality products. One such machine is the granular rolling machine, which plays a crucial role in the production process. In this article, we will explore the different types of granular rolling machines, their applications, and how they contribute to the success of the manufacturing industry.

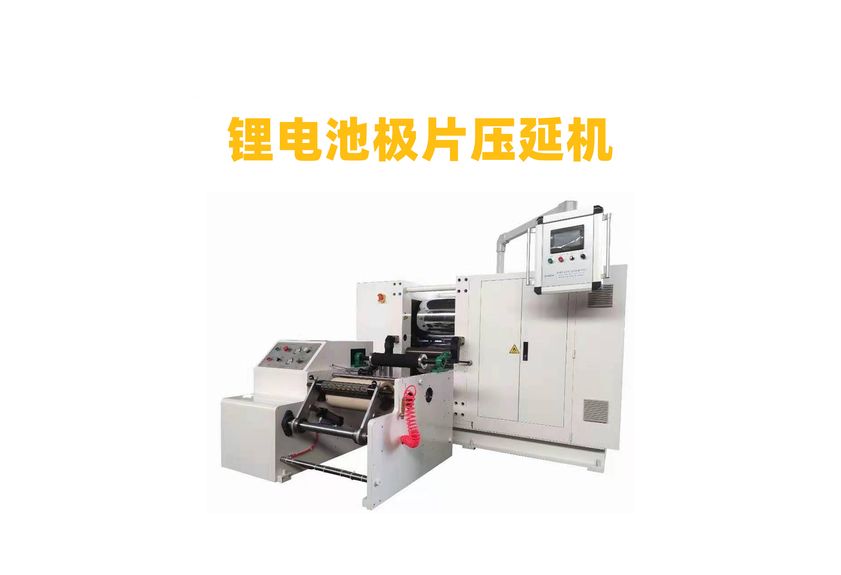

Firstly, let us define what a granular rolling machine is. A granular rolling machine is a type of metalworking equipment that uses a roller to roll over a sheet of metal or other material. This process involves applying pressure to the material, causing it to be flattened and smoothened. The resulting product is often referred to as a "granule" or "rolled sheet."

There are several types of granular rolling machines available in the market, each with its own unique features and capabilities. Some of the most common types include:

1. Flattening rollers: These are the most basic type of granular rolling machine and are used for flattening sheets of metal. They consist of a pair of rollers that apply pressure to the material, causing it to be flattened and smoothened.

2. Circular rolling machines: These machines are designed to roll sheets of metal into circular shapes. They have a rotating drum that applies pressure to the material, causing it to be flattened and formed into a circular shape.

3. Sheet metal rolling machines: These machines are used for shaping sheets of metal into various shapes and sizes. They have a variety of rollers that can be adjusted to create different shapes and sizes.

4. Extrusion machines: These machines are used for shaping sheets of metal into profiles and profiles. They have a pair of extruding rollers that apply pressure to the material, causing it to be extruded and formed into the desired shape.

Applications of granular rolling machines are numerous and varied. Some of the most common applications include:

1. Automotive manufacturing: Granular rolling machines are used in the automotive industry to produce sheet metal parts such as body panels, doors, and roofs. These machines are essential for creating the sleek and stylish look of modern cars.

2. Aerospace manufacturing: Granular rolling machines are used in the aerospace industry to produce lightweight and durable materials such as aluminum alloys. These machines are critical for creating components that require high strength and durability.

3. Plastics manufacturing: Granular rolling machines are also used in the plastics industry to produce sheets of plastic material. These machines are essential for creating various products such as bags, bottles, and containers.

4. Metalworking: Granular rolling machines are used in the metalworking industry to produce sheet metal parts such as stampings, extrusions, and profiles. These machines are essential for creating intricate designs and shapes that require high precision and accuracy.

In conclusion, granular rolling machines play a crucial role in the manufacturing industry by providing a versatile and efficient means of shaping and processing materials. From automotive parts to aerospace components, from plastic sheets to metalworking products, granular rolling machines are essential tools for achieving high-quality results. As technology continues to advance, we can expect to see even more innovative and advanced granular rolling machines on the market, further enhancing the efficiency and effectiveness of the manufacturing industry.