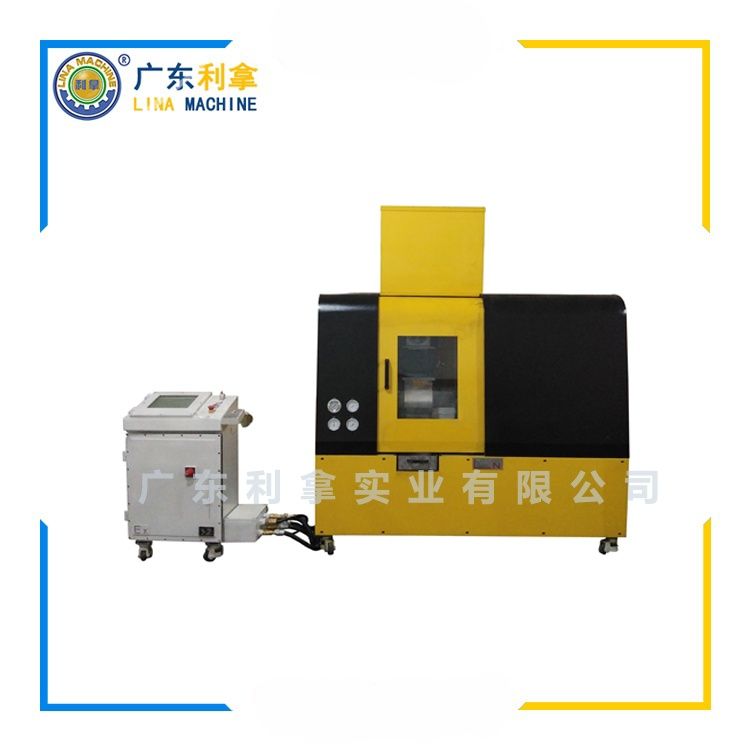

The Open-Closed Mixing Machine: A Revolutionary Tool in the Manufacturing Industry

The open-close mixing machine, also known as a closed-closed mixer, is an essential tool in the manufacturing industry. It is designed to mix and knead materials with high efficiency and accuracy, making it ideal for various applications such as food processing, chemical manufacturing, and plastics production. In this article, we will explore the features, advantages, and benefits of this innovative machine.

Features of the Open-Closed Mixing Machine:

1. High Efficiency: The open-close mixing machine uses advanced technology to achieve high-speed mixing, which can significantly reduce the time required for material processing. This not only saves labor but also improves productivity.

2. Flexible Design: The machine comes in various sizes and configurations, allowing users to choose the one that best suits their needs. Whether you need a small batch mixing system or a large-scale industrial blender, there is a model that fits your requirements.

3. Easy Maintenance: The open-close mixing machine is easy to maintain and clean, making it suitable for use in various environments. Its parts are designed to be replaceable, ensuring longevity and reliability.

4. Safety Features: The machine is equipped with safety features such as automatic shut-off systems and emergency stop buttons, which help prevent accidents and ensure the safety of the operator.

Advantages of the Open-Closed Mixing Machine:

1. Cost-Effective: Compared to other mixing machines, the open-close mixing machine is more cost-effective due to its high efficiency and long lifespan.

2. Versatile Applications: The machine can be used for a wide range of materials, including plastics, rubber, metals, and chemicals. This makes it a versatile tool for many industries.

3. Energy-Saving: The open-close mixing machine uses less energy than traditional methods, reducing operating costs and environmental impact.

Benefits of the Open-Closed Mixing Machine:

1. Improved Quality: The machine's high-speed mixing ensures that the final product has better quality and consistency, leading to increased customer satisfaction.

2. Increased Productivity: With the open-close mixing machine, production can be completed faster, reducing downtime and increasing overall productivity.

3. Better Control: The machine allows for precise control of the mixing process, enabling users to adjust settings according to their specific needs, resulting in better product quality.

In conclusion, the open-close mixing machine is a revolutionary tool in the manufacturing industry. Its high efficiency, flexible design, easy maintenance, safety features, and cost-effectiveness make it an essential investment for any business looking to improve their production processes. By choosing this machine, businesses can achieve better quality products, increased productivity, and improved control over their operations.