The EVA, TPR, and PVC Pellet Production Line

The production line for EVA (Ethylene Vinyl Acetate), TPR (Thermoplastic Rubber), and PVC (Polyvinyl Chloride) pellets is a crucial step in the manufacturing process of these materials. This article will provide an overview of the key components and processes involved in this line, as well as their benefits and challenges.

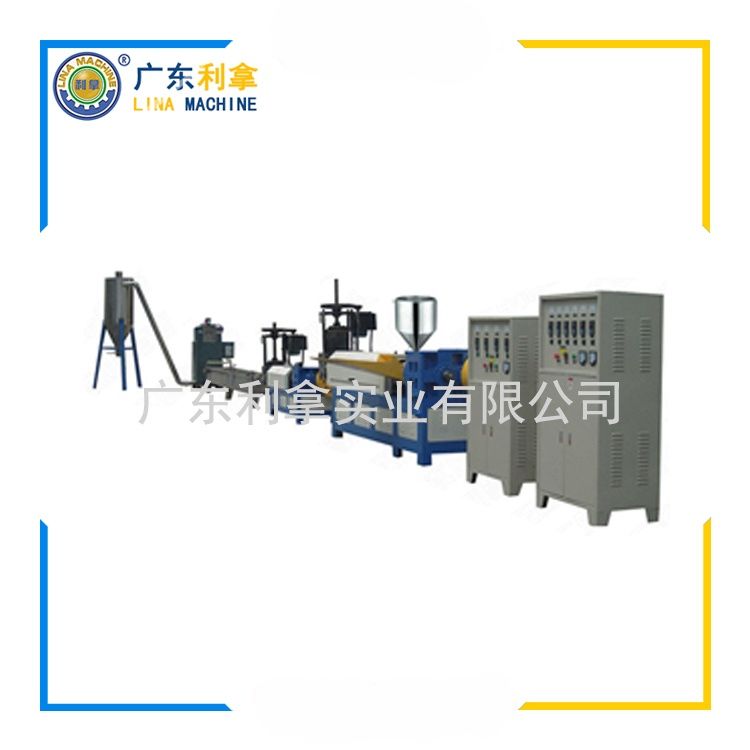

Firstly, the raw materials are fed into the system through a feeder. These materials include polyethylene, polypropylene, and other polymers that can be processed into pellets. The feeder ensures that the correct amount of material is delivered to the extruder, which is responsible for melting the polymer and forming it into a uniform mass.

The extruder is a critical component of the production line. It consists of a barrel, screw, and die. The barrel contains the molten polymer, while the screw rotates it through the die, which creates the desired shape and size of the pellets. The die is designed to ensure that the pellets have a consistent thickness and density, which is important for their quality and performance.

Once the pellets are formed, they are collected by a scraper and transported to a cooling station. Here, they are cooled down to prevent them from melting again and to set the final shape. The cooling station also helps to remove any residual heat from the pellets, ensuring that they are ready for further processing or storage.

Finally, the pellets are packaged and shipped to their intended destination. The packaging should protect the pellets from damage during transportation and storage. Additionally, it should meet the regulatory requirements of the industry, such as labeling and safety standards.

In conclusion, the EVA, TPR, and PVC pellet production line is a complex system that requires careful attention to detail. From the raw materials to the final packaging, every step plays a crucial role in ensuring the quality and consistency of the final product. By understanding the key components and processes involved in this line, manufacturers can optimize their operations and improve their overall efficiency and profitability.