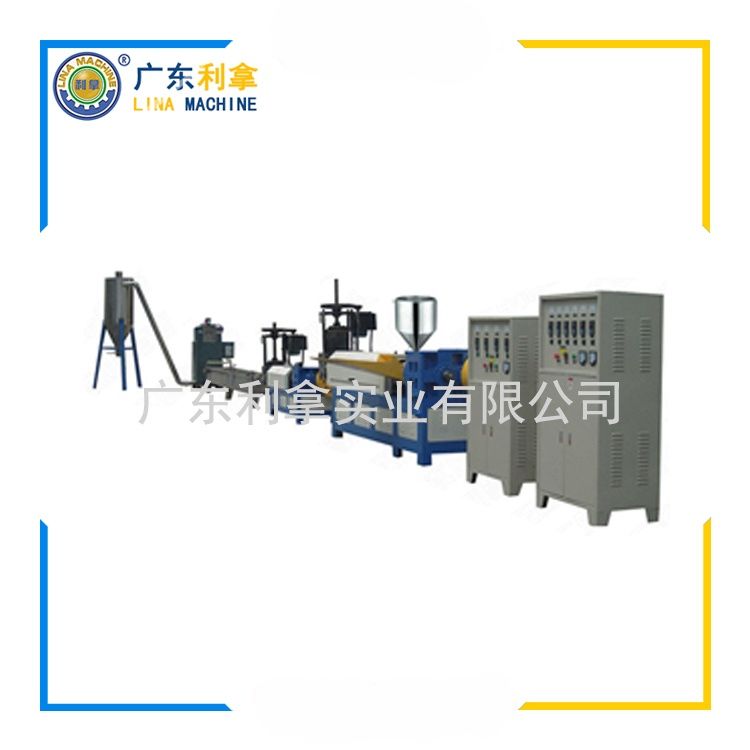

The Low-Smoke and Zero-Halogen Pelletizer

The low-smoke and zero-halogen pelletizer is a crucial tool in the manufacturing industry, particularly in the production of electrical and electronic components. This machine uses advanced technology to produce pellets that are free from harmful substances such as halogen, making them ideal for use in electronic devices.

One of the key features of this pelletizer is its ability to produce pellets with a low smoke emission. This is achieved through the use of advanced filtration systems that remove any remaining halogen or other harmful substances from the pellets before they are produced. This not only reduces the risk of fire hazards but also improves the overall quality of the product.

Another important aspect of this pelletizer is its ability to produce pellets that are completely free of halogen. This is achieved through the use of specialized equipment that ensures that all halogen is removed during the production process. This means that the pellets produced by this machine are safe for use in electronic devices, providing a safer alternative to traditional halogen-based materials.

In addition to these benefits, this pelletizer also produces pellets with a high degree of uniformity. This is achieved through the use of advanced control systems that ensure that the pellets produced are consistent in size and shape. This makes it easier to handle and transport the pellets, while also ensuring that they meet the required specifications for use in electronic devices.

Overall, the low-smoke and zero-halogen pelletizer is an essential tool in the manufacturing industry, providing a safer and more efficient way to produce pellets. Its advanced technology and focus on safety and quality make it an ideal choice for those looking to produce pellets that meet strict standards for use in electronic devices.