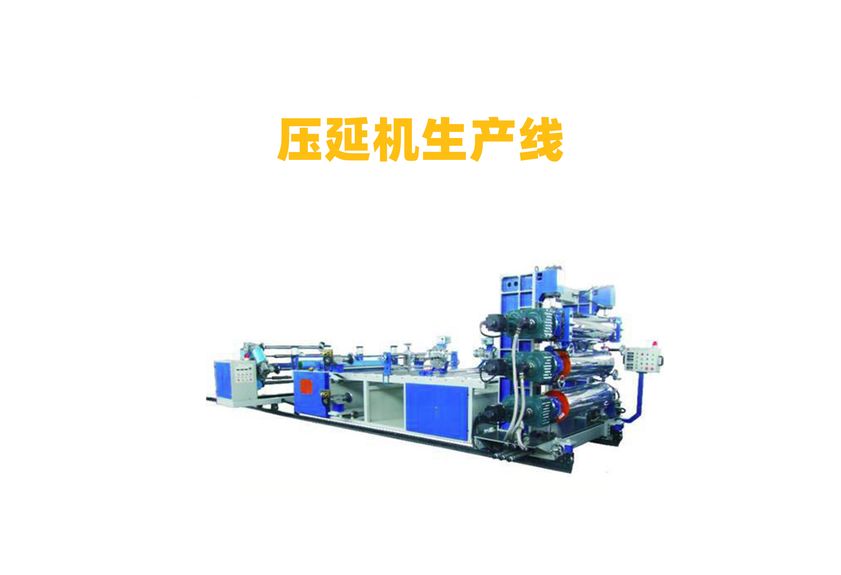

The Two-Roll Rolling Mill: A Detailed Guide to Its Functions, Applications, and Maintenance

The two-roll rolling mill is a crucial piece of machinery in the metalworking industry. It is used for shaping metal sheets into various shapes and sizes by applying pressure and heat to them. In this article, we will explore the functions, applications, and maintenance of this machine.

Functions:

1. Shaping Metal Sheets: The two-roll rolling mill is primarily used for shaping metal sheets into desired shapes and sizes. This process involves applying pressure to the sheet using two rollers, which are mounted on a frame. The rollers rotate at different speeds to achieve the desired thickness and width of the sheet.

2. Heat Treatment: The two-roll rolling mill can also be used for heat treatment of metal sheets. During this process, the sheet is heated to a high temperature and then pressed between the rollers to achieve a desired hardness and strength.

3. Precision Work: The two-roll rolling mill is ideal for precision work, as it can produce very accurate and uniform sheets with minimal defects. This makes it suitable for use in industries such as automotive, electronics, and medical equipment.

Applications:

1. Automotive Manufacturing: The two-roll rolling mill is widely used in the automotive industry for manufacturing parts such as engine blocks, transmissions, and wheels. By shaping metal sheets into these components, manufacturers can save time and money while ensuring high quality and consistency.

2. Electronics Manufacturing: The two-roll rolling mill is also essential in the electronics industry for producing circuit boards, connectors, and other electronic components. The precision and consistency achieved through this process make it an ideal choice for high-end electronics manufacturers.

3. Medical Devices: The two-roll rolling mill is used in the medical device industry to manufacture parts such as surgical instruments, implants, and prosthetics. The ability to produce precise and uniform sheets ensures that these devices meet strict safety standards and provide optimal patient care.

Maintenance:

To ensure the longevity and efficiency of the two-roll rolling mill, regular maintenance is necessary. Here are some tips for maintaining this machine:

1. Regular Checks: Perform regular checks on the rollers, bearings, and other moving parts to detect any wear or damage. This will help prevent breakdowns and ensure smooth operation of the machine.

2. Lubrication: Ensure that all moving parts are properly lubricated to reduce friction and extend the life of the machine. Use appropriate lubricants based on the manufacturer's recommendations.

3. Cleanliness: Keep the machine clean by regularly removing debris and dust from the rollers and other parts. This will prevent corrosion and improve the performance of the machine.

1. Two-roll rolling mill

2. Metalworking industry

3. Shaping metal sheets

4. Heat treatment

5. Precision work

6. Automotive manufacturing

7. Electronics manufacturing

8. Medical devices

9. Maintenance

10. Lubrication

11. Cleanliness

The two-roll rolling mill is a critical tool in the metalworking industry, used for shaping metal sheets into various shapes and sizes. It is widely used in automotive, electronics, and medical device manufacturing, where precision work is essential. To ensure the longevity and efficiency of this machine, regular maintenance is necessary, including regular checks, lubrication, and cleaning. By following these best practices, you can optimize the performance of your two-roll rolling mill and achieve maximum productivity.